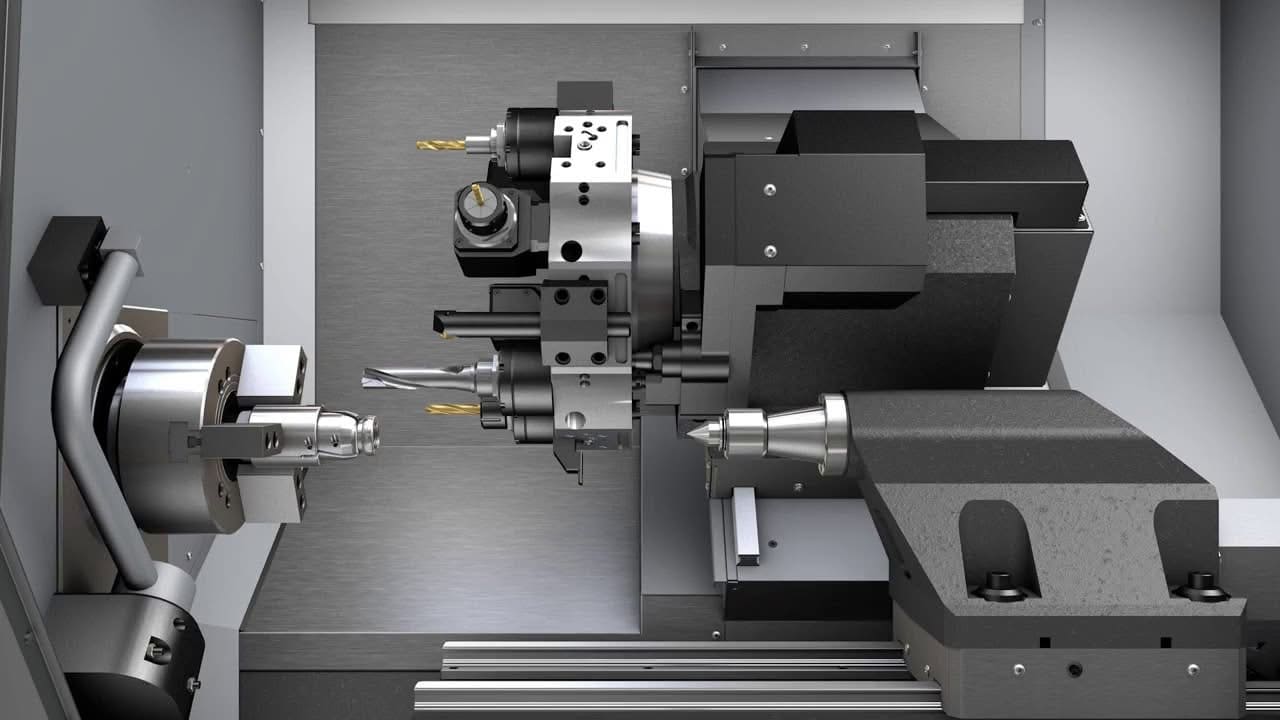

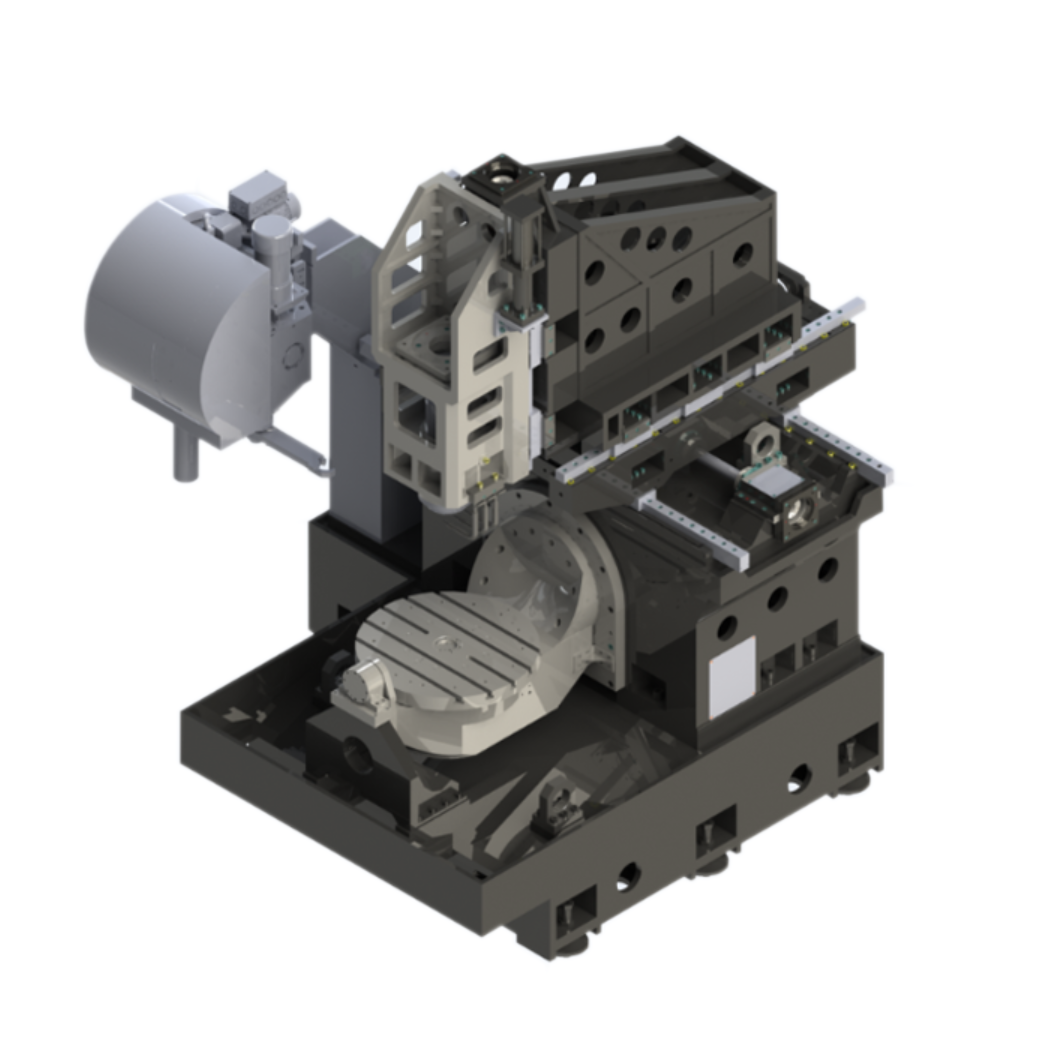

5-axis machining is a crucial component of CNC machining. This technology has been widely adopted in industries such as shipbuilding, aerospace, automotive, light industry, and medical equipment manufacturing, where high-precision instruments are produced. In traditional mould machining, three-axis machining centres and vertical machining centres are commonly used for milling operations. However, as China’s mould manufacturing technology continues to advance, the limitations of traditional vertical machining centres and three-axis machining centres have become increasingly apparent. Currently, ball-nose milling cutters are widely used in mould machining. While the use of ball-nose milling cutters in mould machining offers obvious advantages, when applied to vertical machining centres, their bottom surface linear speed is zero, and surface finish is poor. By using a five-axis machining centre for mould processing, these shortcomings can be completely overcome.

Advantages of 5-axis machining

5-axis machining is highly efficient and precise, and the workpiece can be completed in one clamping. It is suitable for the processing of modern molds such as automotive parts and aircraft structural parts. Five-axis machining is not only used in the civil industry, but also widely used in the aerospace, military, scientific research, precision instruments, and high-precision medical equipment industries. 5-axis machining is a high-tech method that turns the impossible into the possible. All spatial surfaces or unusual shapes can be processed or produced. It can not only complete the machining tasks of complex parts and industrial products, but also quickly improve the processing efficiency and shorten the processing process.

Advantages of five-axis machining tools

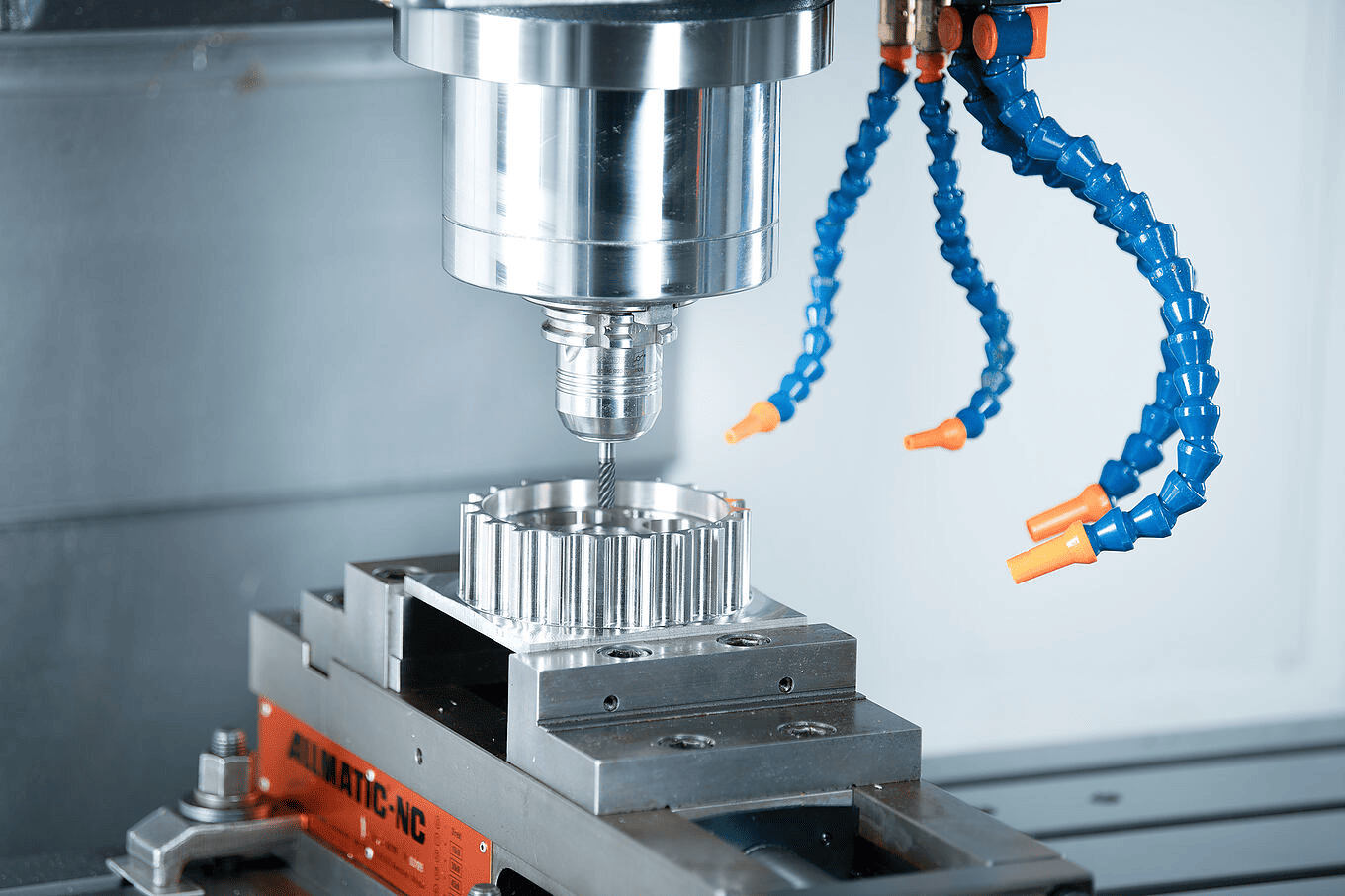

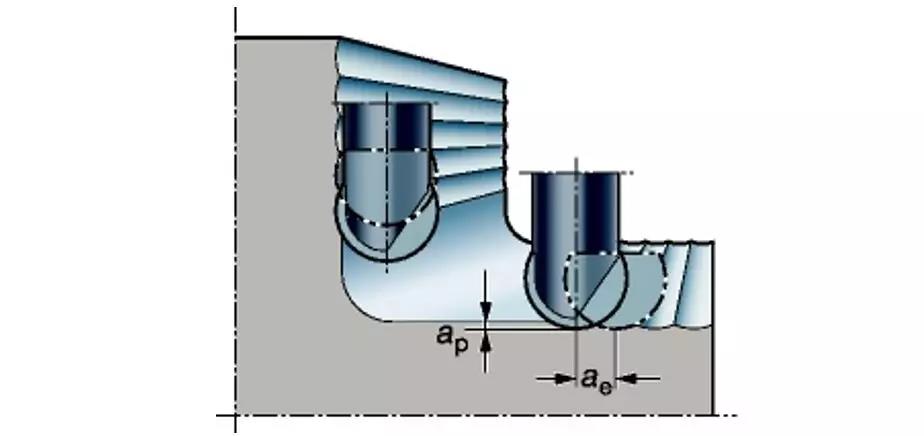

In five-axis machining, the use of flat-bottom end mills can keep the complex mold machining surface vertical, which can greatly reduce the machining time. The principle of the five-axis machining center is also applicable to side milling with angled surfaces, which can eliminate the rib-like texture caused by ball-end end mills, making the surface quality of the mold more ideal and reducing the workload of manual milling and manual work required to clean the mold surface.

The tools used in five-axis machining are shorter, and the entire part can be machined at one time without the need for re-clamping or the use of longer tools required in similar three-axis machining. The mold can be made in a shorter time and the surface quality of the part is better.

Advantages of 5-axis machining workpiece clamping

5-axis machining offers high efficiency and precision, with parts completed in a single setup. It is ideal for the production of modern moulds such as automotive components and aircraft structural parts. Five-axis machining is not only used in civilian industries but also widely applied in aerospace, military, research, precision instruments, and high-precision medical equipment sectors. Five-axis machining is a high-tech method that turns the impossible into the possible, enabling the machining or production of all spatial surfaces or unusual shapes. It not only completes complex parts and industrial product machining tasks but also rapidly improves machining efficiency and shortens the machining process.

Application of five-axis machining center in automobile mold processing

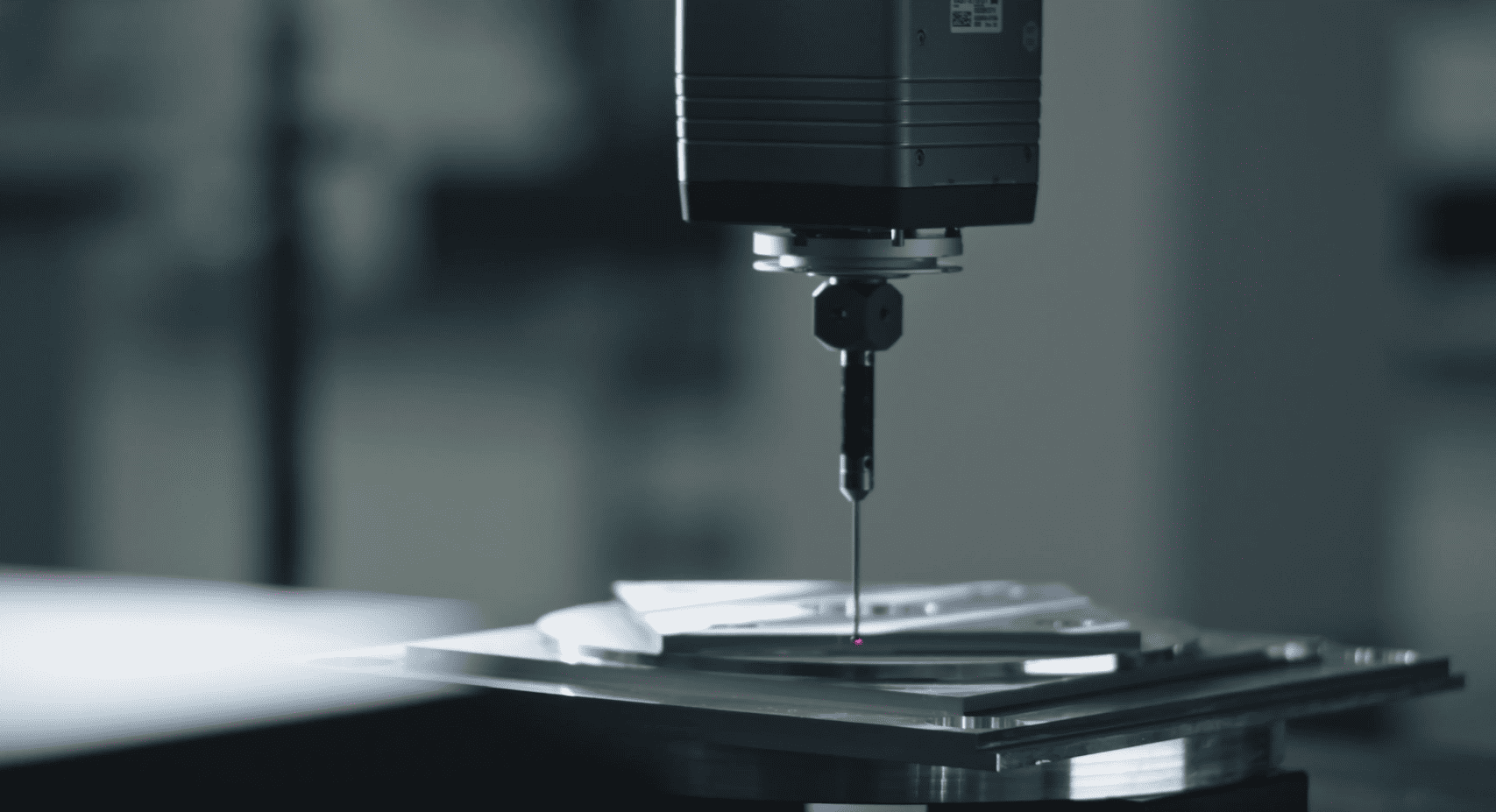

At present, the CAD system is mainly used to design automobile parts, and the design of parts is completed through reverse engineering and various tests. CAM software is used to process the complex surface of the mold. However, how to ensure the accuracy of design and processing depends on CNC machining. In the following article, we analyze the relationship between the application of five-axis machining centers in mold processing and the quality of automobile molds.

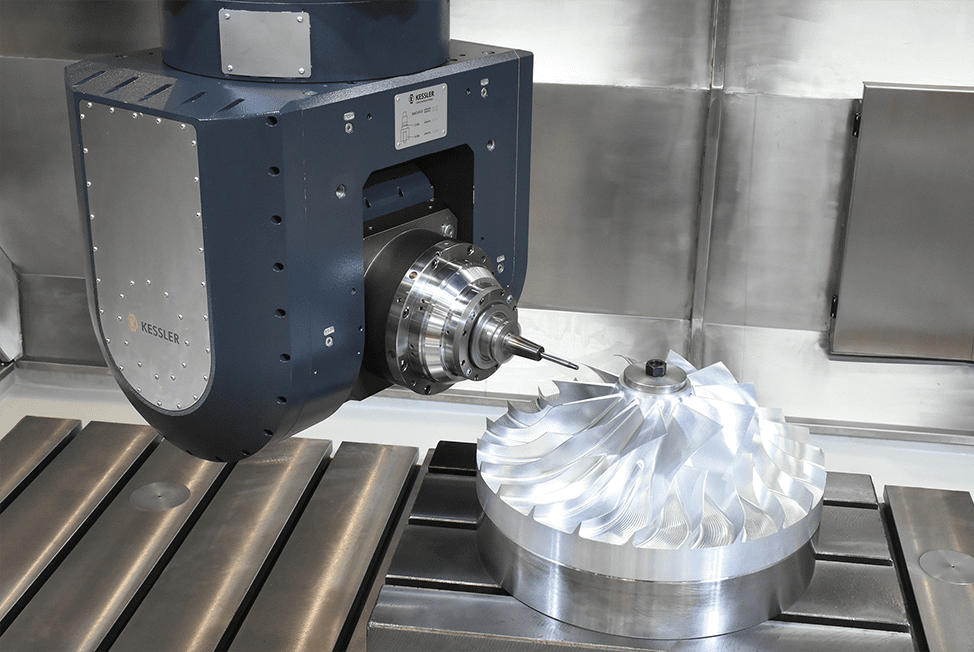

Processing of deep cavity molds

In the process of automobile mold manufacturing, when processing deep cavity molds, if a three-axis machining center is used, the tool holder and tool must be lengthened to achieve this. However, when using a five-axis machining center to process deeper and steeper cavities, in order to create better process conditions for mold processing, additional rotation and swing of the workpiece or spindle head can be used to shorten the tool length appropriately, thereby eliminating the occurrence of collisions between the tool and the tool bar and the cavity wall, reducing tool jitter and breakage during processing, extending the service life of the tool, and greatly improving the surface quality and processing efficiency of the mold.

Processing of mold side wall

For the processing of the mold side wall, the tool length of the three-axis machining center should be greater than the side wall depth, and the tool length is also determined by the side wall depth. If the tool length is increased, its strength will be significantly reduced. If the tool length is higher than 3 times the diameter, the tool yield phenomenon will occur, and the quality of the workpiece will be difficult to guarantee. If the five-axis machining center is used to process the mold side wall, the spindle or the workpiece can be swung to make the tool and the mold side wall appear vertical. When milling the mold side wall, a flat milling cutter can be used, which can improve the workpiece quality and extend the tool life.

Flatter surface processing of mold

When machining the flatter curved surface of the mold, the three-axis machining center needs to use ball cutters for fine milling to obtain good surface quality. In this case, it is necessary to increase the tool path, but the center rotation linear speed of the ball-end cutter is almost zero. The degree of tool damage during mold machining is large, the tool life will be shortened, and the mold surface quality will also deteriorate. When machining a flatter curved surface with a five-axis machining center, the tool can be placed at a certain angle on the workpiece before machining the workpiece, which can increase the relative linear speed between the workpiece and the ball-end cutter, which can not only increase the tool life, but also greatly improve the workpiece surface quality.

Processing of irregular mold surfaces

In the past, the processing of molds with irregular surfaces was generally completed by three-axis machining centers. The direction of the tool cutting the mold is to move along the entire cutting path, and the cutting process will not change. At this time, the cutting state of the tool tip cannot guarantee the perfect quality of each part of the mold. Molds with frequent changes in curvature and molds with deep grooves can be processed by five-axis machining centers. The cutting tool can always achieve the best cutting state. The tool can maximize the optimization of the direction of the entire processing path, and the tool can also move in a straight line at the same time, so every part of the mold surface will be more perfect.

Processing of different mold geometries

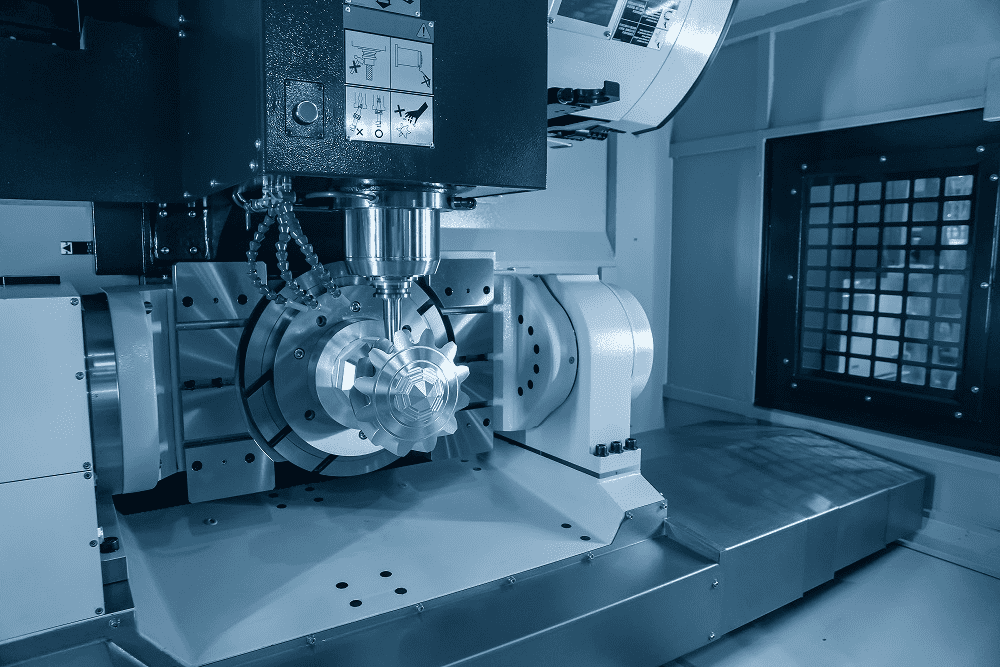

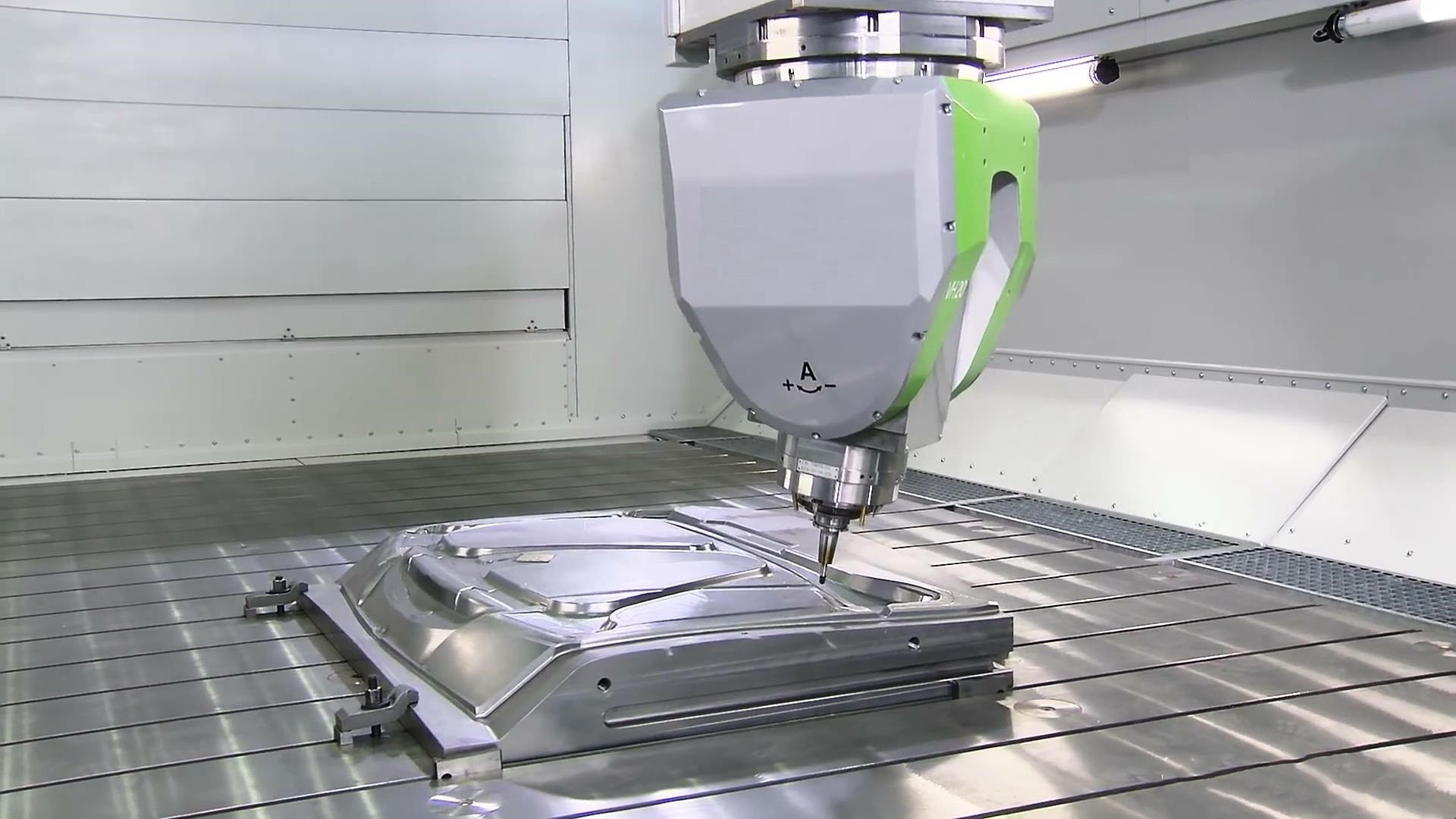

When using a five-axis machining center to process molds with three-dimensional curved planes, the cutting process of the mold is always protected in the best working state, and the working angle of the tool can be changed in any area of the machine tool processing to complete the processing of geometric molds.

Processing of inclined holes on the inclined surface of the mold

When machining the inclined surface and inclined holes of the mold, the five-axis machining center can place the spindle on the vertical side of the workpiece inclined surface and position it at the accurate hole position through the swing head machining action of the swing head machine tool. In order to accurately machine the inclined hole on the mold, at least two linear axes need to interpolate, and the accuracy of the hole position is significantly reduced in this process. If a swing table-type five-axis machining center is used to machine the inclined surface of the mold, the action is to place the inclined surface of the mold at a position perpendicular to the spindle through the machine tool swing table. The machining of the inclined hole can be completed by the single movement of one of the linear axes of the spindle, which can significantly improve the accuracy of the hole.

Milling of straight lines without direction changes in molds

If you want to mill a straight line without changing the direction, just draw a straight line with the tool tip. If the direction needs to be changed, draw a curve with the tool tip. The direction of the tool tip has been changed. If you want a straight line again, you must give the necessary compensation to this curve. This is extremely important when using a five-axis machining center. If the control system does not take into account the length of the tool, the tool rotates around the center of the axis. The tool tip cannot be fixed and is likely to move out of the current working position. However, the system of the five-axis machining center has a five-axis control function.

In the operation of machining molds, the five-axis control system is used. Although the direction of the tool is changed, the position of the tool tip can remain unchanged. In this process, the necessary compensation movements of the x, y, and z axes are also automatically calculated, and the machining accuracy is significantly improved.

In short, in mold processing, the 5-axis machining center can avoid tool interference and can process complex parts that are difficult to process with ordinary three-coordinate machine tools.For the processing of straight-grained surface molds, the side milling one-knife forming technology can be used, which has good processing quality and high efficiency.

For three-dimensional surfaces, especially large and flat surfaces, the large-diameter end mill can be used to approach the large surface for processing, the number of passes will be reduced, the residual height is small, and the processing efficiency and surface quality can be effectively improved.Multiple spatial surfaces of the mold can be clamped at one time for multi-process and multi-faceted processing, which improves the processing efficiency and can effectively improve the accuracy of the relative positions of each surface.When the 5-axis machining center processes the mold, for the workpiece, the tool can always be in the most effective cutting state. In some processing sites, large-size tools can be used to avoid mutual interference. This kind of tool has good rigidity, and the processing accuracy and processing efficiency can be improved. Therefore, the processing adaptability of the 5-axis machining center is relatively wide and it is worth promoting widely.