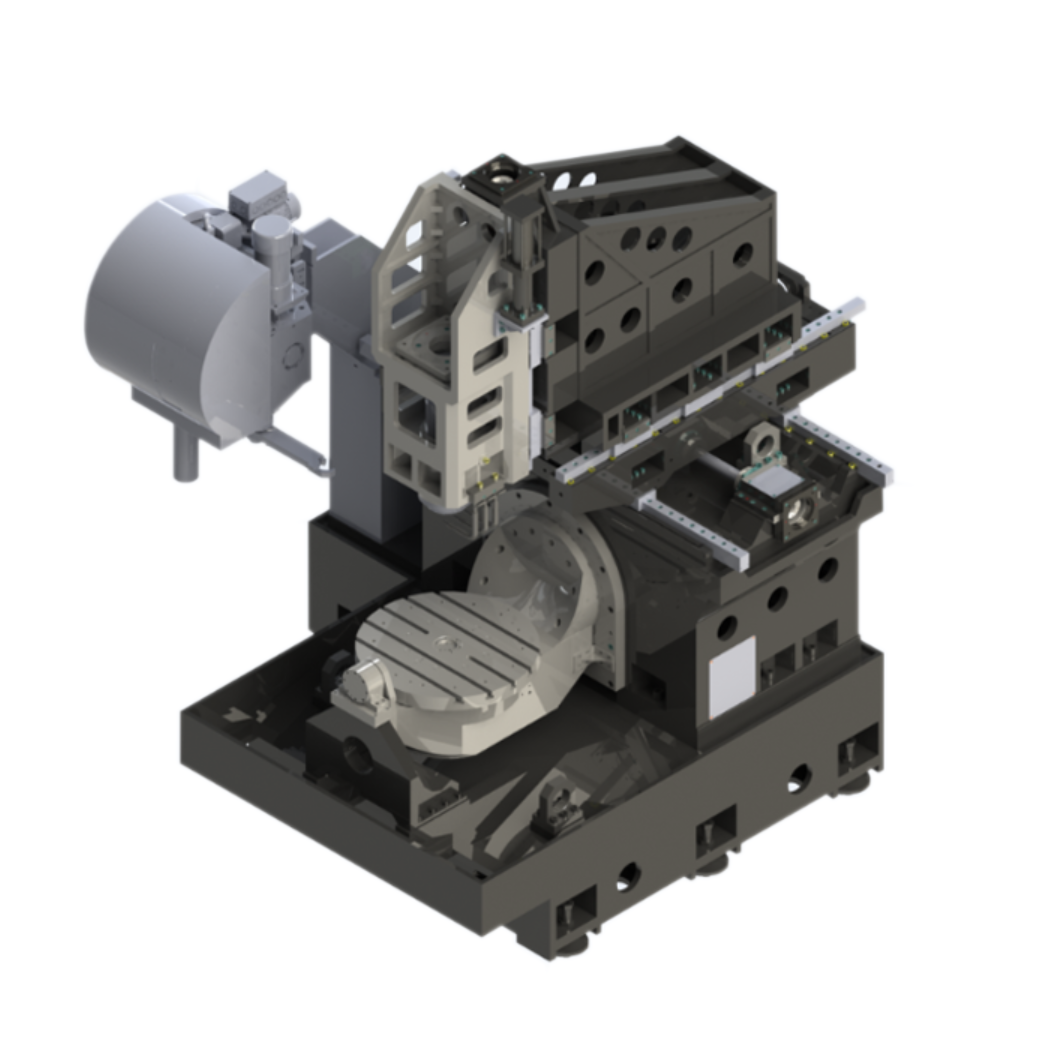

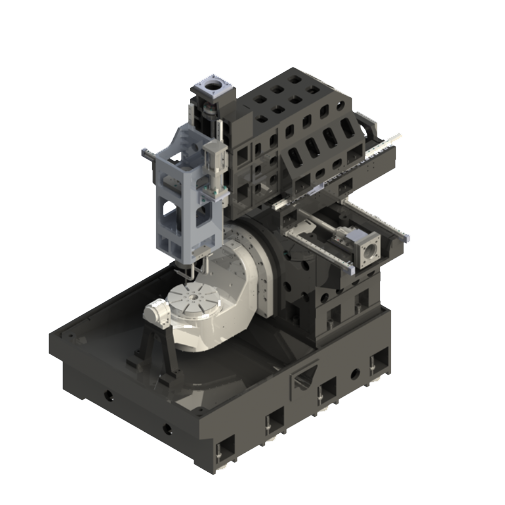

5 Axis Machining Center Features:

· 5 axis vertical machining center equipped with HIWIN RAB series Torque Motor rotary table, table diameter 650mm.

· The 5 axis vertical machining center has RTCP function, and the 5-axis linkage can complete complex processing such as spatial surfaces and inclined holes.

· Efficient toolpaths are generated by CAM software to reduce empty strokes and improve cutting efficiency.

· The 5-axis machining center is equipped with a quick tool change system and a tool magazine with a capacity of 24 tools, supporting continuous multi-process machining.

· The machining centre is equipped with a Renishaw tool setting TS27R and Renishaw probe OMP60.

· Wide range of applications: aerospace (high-precision milling of engine blades, cabin frames), automotive moulds (deep cavity machining and surface finishing of cover moulds), medical field (machining of complex surfaces and microstructures of artificial joints), material diversity (machining of metallic steels, aluminium, titanium alloys, composites and even ceramics).

|

Model |

TOM-WZ650B |

|

|

Travel |

X axis |

820mm |

| Y axis |

520mm |

|

| Z axis |

500mm |

|

| The distance from the center of the spindle to the guide rail. |

187mm |

|

| The distance from the spindle end face to the turntable. |

150-650mm |

|

|

Table |

Table size |

Ф650 |

| Max. load |

300kg |

|

| T slot |

18H7 |

|

|

Spindle |

Type |

Direct connection |

| Speed |

12000rpm |

|

| Spindle diameter |

150mm |

|

| Spindle taper |

BT40 |

|

| Main motor |

15kw |

|

|

Screw |

X axis |

4012 |

| Y axis |

4012 |

|

| Z axis |

4012 |

|

|

Line rail |

X axis |

RG45HA |

| Y axis |

RG45HA |

|

| Z axis |

RG45HA |

|

|

5- axis Turntable |

Table diameter. |

650mm |

| 0°load |

300kg |

|

| 90°load |

100kg |

|

| X/Y/Z axis fast movement speed. |

24M/min |

|

| Machine | Weight |

9500kg |