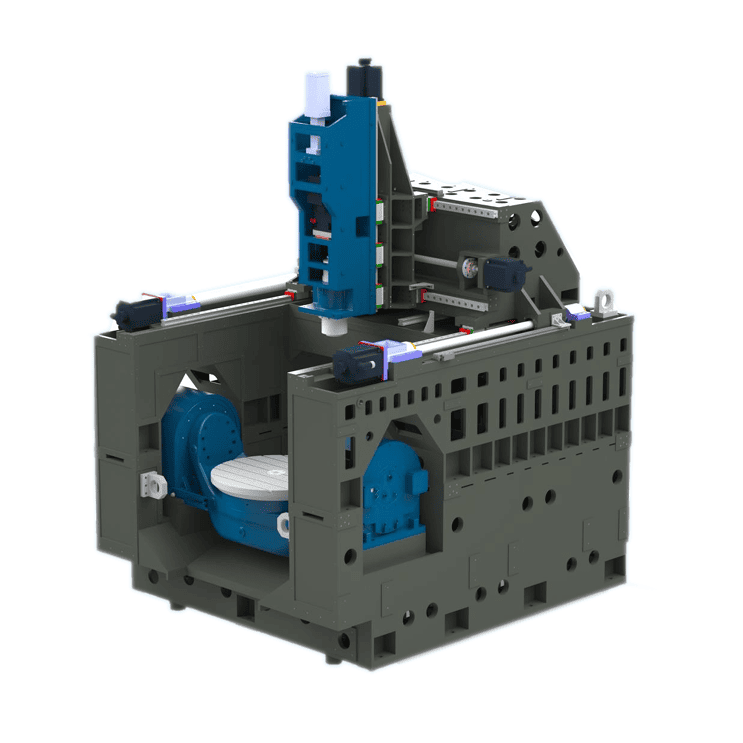

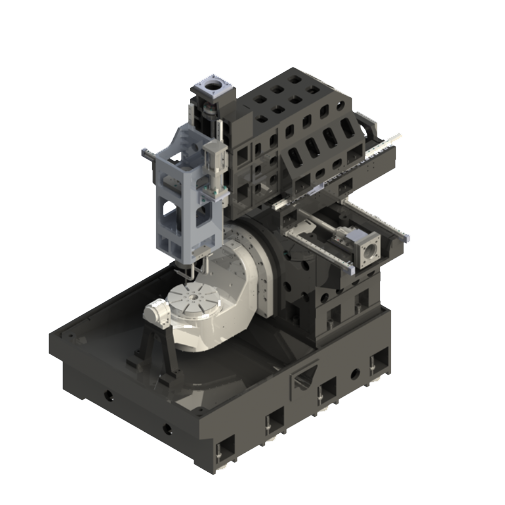

Slant Bed CNC Lathe Machine Feature:

· The Slant bed rails have a wide span, and the force distribution on the Z and X axes is more even, reducing the risk of deformation.

· The spindle power can reach 15kW and has large torque, making it suitable for difficult-to-process materials such as stainless steel and titanium alloy.

· Multi-station turret, standard 8-12 station servo turret (some models support power tools), tool change time ≤ 0.2 seconds, support turning and milling composite processing.

· TCK600 slant bed cnc lathe adopts high-precision linear guide rails (or hard rails + plastic lamination process) and pre-tightened ball screws, with a repeat positioning accuracy of up to ±0.004mm.

| Specifications

|

Unit | TCK600 |

| Swing over bed | mm | Φ630

|

| Swing over slide

|

mm | Φ400 |

| Max machining length

|

mm | 600/900 |

| Spindle head form

|

– | A2-8/A2-11 |

| Spindle motor power

|

kw | 11-15 |

| Max spindle speed

|

rpm | 2500/2000 |

| Diameter of spindle through hole

|

mm | Φ90/105 |

| Inner diameter of pull through hole

|

mm | Φ75/90 |

| Turret form

|

– | 12-station hydraulic turret |

| Hydraulic chuck

|

inch | 12‘‘/10“ |

| X-axis travel

|

mm | 315 |

| Z-axis travel

|

mm | 750/1000 |

| X/Z axis motor torque

|

N.m | 15/15 |

| Specification of X/Z screw

|

– | 4010/4010 |

| Repeat positioning accuracy

|

mm | ±0.004 |

| Tool size

|

mm | 25×25/40 |

| Tailstock sleeve diameter / travel

|

mm | Φ100/120 |

| Sleeve taper

|

MT | 5 |

| Dimensions

|

m | 2.8/3.3×1.8×2.3 |

| Machine weight (about)

|

t | 5.5/6.5 |