Are you struggling to find a 5-axis machining center on a tight budget? Choosing the wrong manufacturer or simply pursuing the lowest price can lead to disastrous investment losses.

The most cost-effective 5-axis machining center in China is not necessarily the cheapest, but rather the one that strikes the best balance between reliable components, strict quality control, and responsive after-sales support, thereby achieving the lowest total cost of ownership over its lifetime.

As the founder of YOUKA, I have been dedicated to helping global customers address this issue for the past decade. I have seen buyers get great deals, and I have also seen people suffer heavy losses because they pursued unbelievable prices. The quote is only the beginning of the story. To find true value, you need to understand the reasons behind it.

Is the cheapest machine really the most cost-effective?

Tempted by ultra-low prices? When the machine breaks down, you face costly downtime and no support, and your initial savings can quickly disappear.

The cheapest machines often turn out to be the most expensive. True cost-effectiveness lies in the total cost of ownership, which includes uptime, maintenance, and after-sales support. A reliable machine that consistently produces high-quality parts is always cheaper than a low-cost machine that sits idle.

Let’s delve deeper into this issue, as it is the most important lesson I have learned. Early in my career, I witnessed a competitor lose a deal because their price was 15% higher than other factories. The customer was delighted with the deal. Six months later, the customer called us. The spindle of their “cheaper” machine had broken, and they had received no response from the original seller. Their machine had been idle for three weeks, resulting in the loss of an important contract. The losses incurred due to downtime far exceeded the initial 15% savings.

This is what is meant by ‘Total Cost Of Ownership’. It is not just the purchase price, but the overall financial impact of the machine on your business.

Breakdown of Total Cost of Ownership (TCO)

|

Cost Factor |

The “Cheapest” Machine |

A “Cost-Effective” Machine |

|

Purchase Price |

Very Low |

Competitive |

|

Component Quality |

Lower-grade, unknown brands |

Reliable, well-known brands (e.g., for spindles, guideways) |

|

Quality Control |

Minimal or inconsistent |

Rigorous (geometric tests, performance tests) |

|

Downtime Risk |

High |

Low |

|

After-Sales Support |

Slow or non-existent |

Fast and responsive |

| Cost-Per-Part | High (due to scrap and downtime) |

Low (due to reliability and efficiency) |

At YOUKA, our entire philosophy is built around reducing total cost of ownership (TCO) for our customers. Our excellent cost management system ensures that we offer highly competitive prices, but we never compromise on the quality of core components or rigorous quality testing (geometric accuracy, mechanical accuracy, leak testing, electrical leakage testing). In the long run, a slight increase in initial investment in quality is the best cost-saving strategy.

What key characteristics determine the price and value of a

machine?

Overwhelmed by a long list of technical specifications and components? Paying for features you don’t need is wasteful, but cutting corners on critical components can lead to failure.

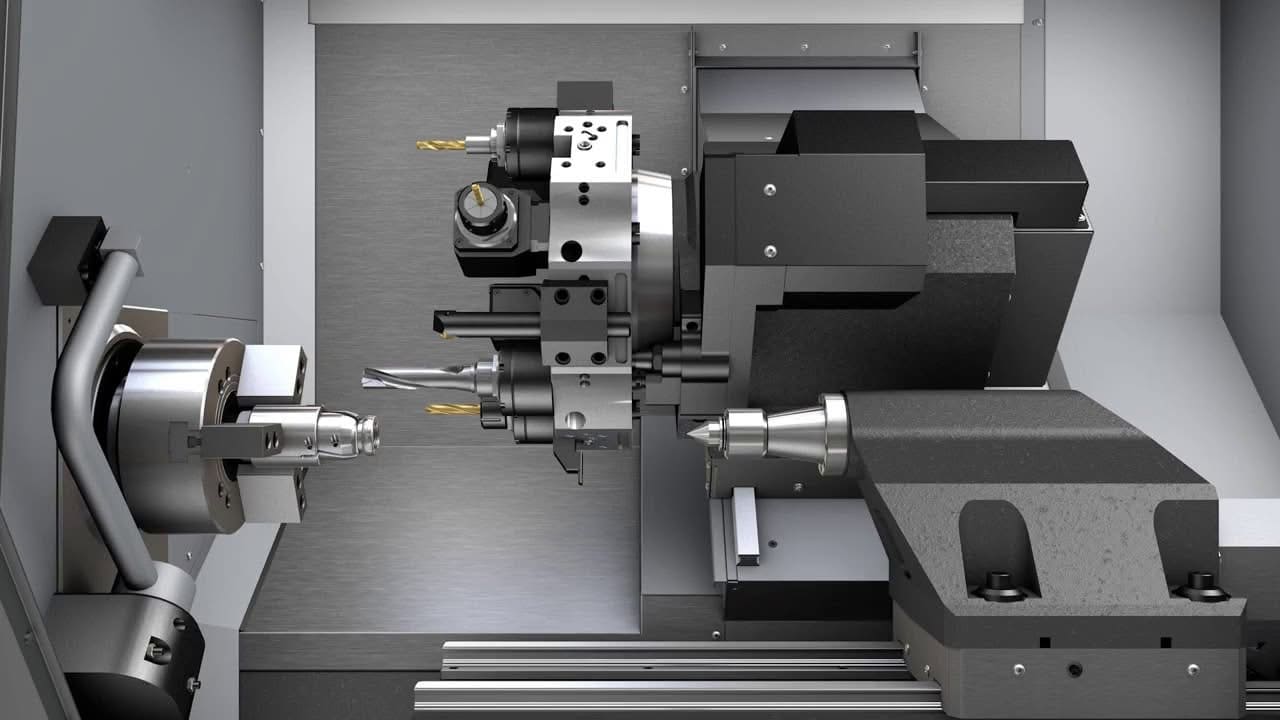

The five major factors that determine the price and long-term value of machine tools are the basic manufacturing quality of the numerical control system, spindle, machine tool castings, guideways, and ball screws. No corners can be cut in these areas. When customers send me quotes from other companies for comparison, I look at these first. They give me an idea of the customer’s expectations for product quality and performance. As a buyer, you also need to pay attention to these details.

Brain: Control System

CNC systems are the heart of machine tools. Top brands like Fanuc and Siemens offer outstanding reliability and extensive global support networks, but they come at a high price. Other reputable systems, such as Syntec, GSK, and HNC, offer outstanding five-axis functionality and are a wise choice for cost reduction without compromising performance, especially when operators have received proper training. Choosing the right CNC system depends on your needs and budget, but it is essential to exercise caution when selecting systems from unknown brands.

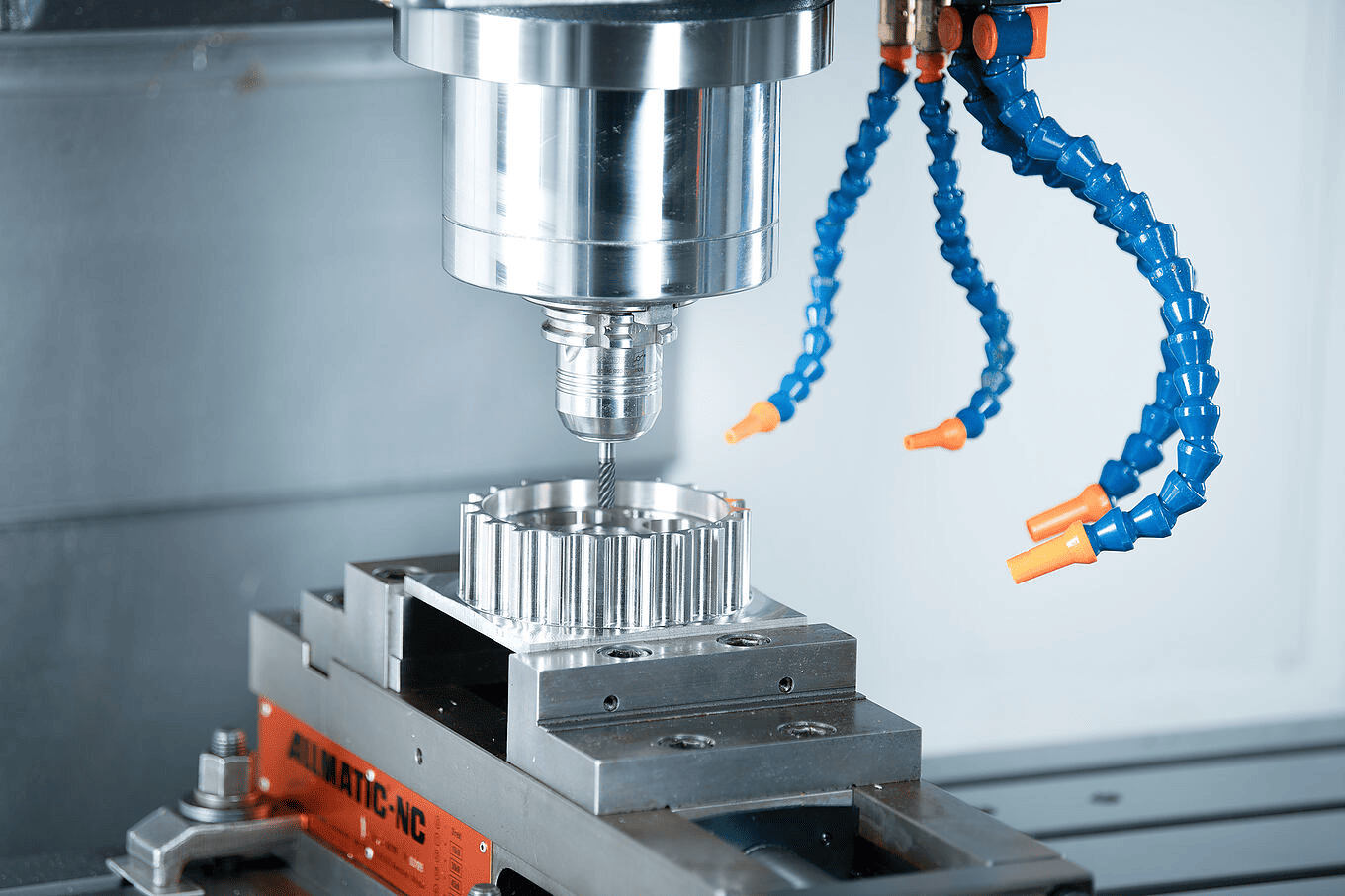

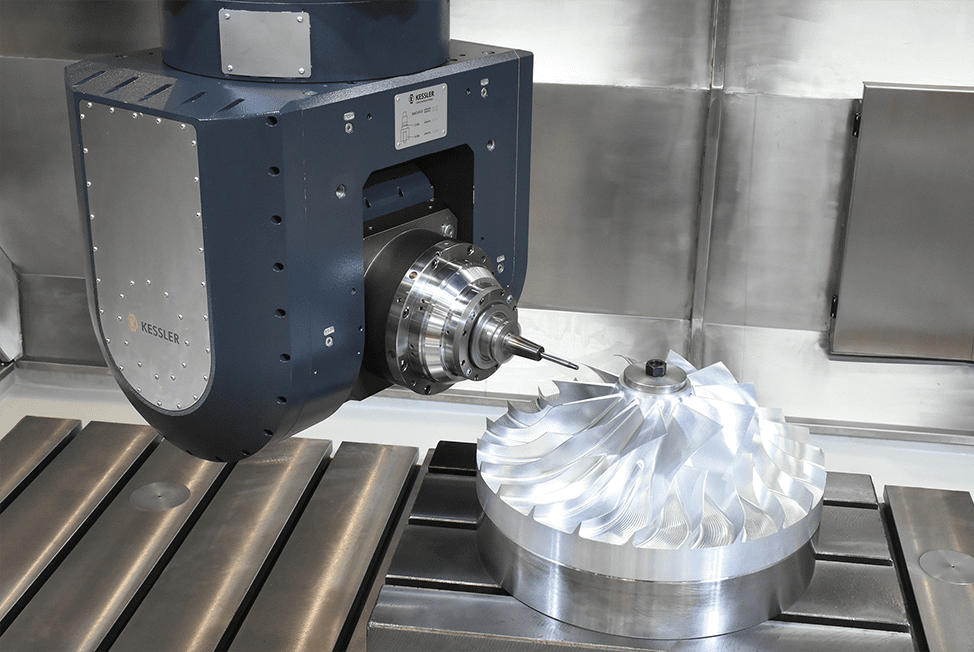

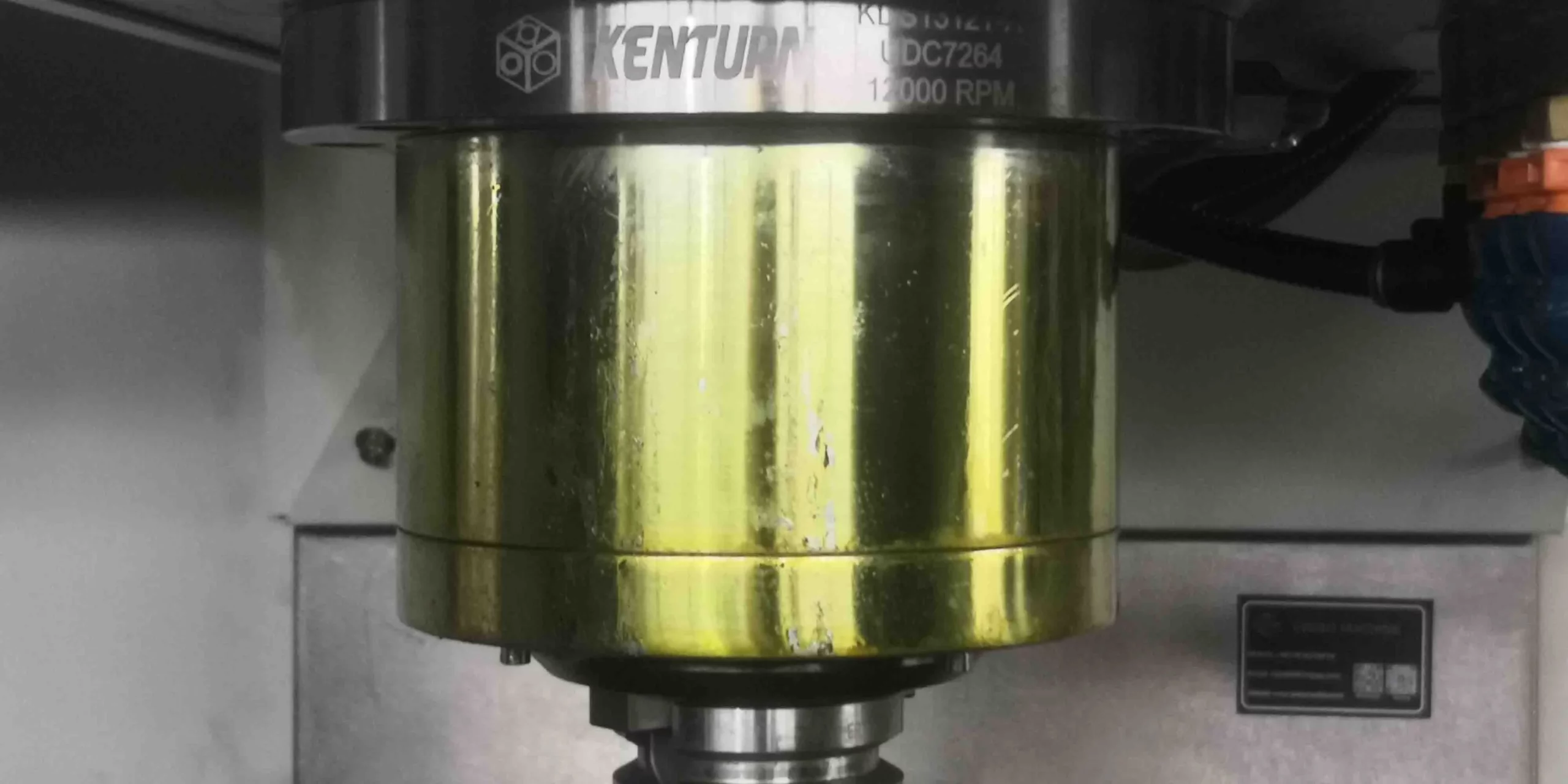

Power: Spindle and drive system

The spindle is responsible for the work. Its speed (RPM) and power (kW) must match the material you are cutting. Cutting aluminium requires high speed, while cutting steel requires high torque. It is crucial to choose a spindle manufactured by a reputable manufacturer. OKADA, ROYAL, and Kenturn are all excellent choices.

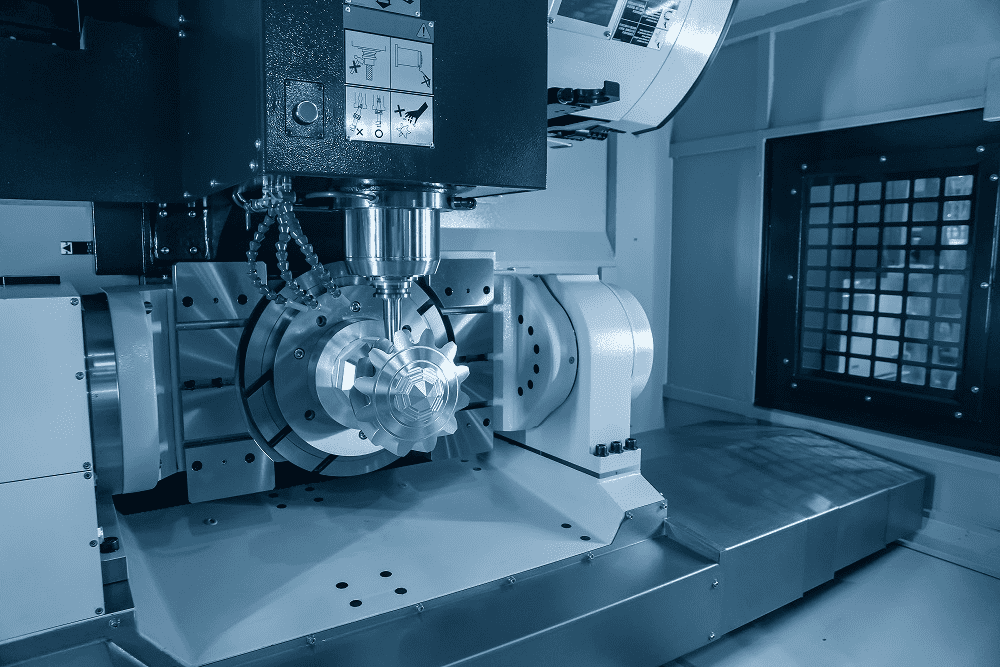

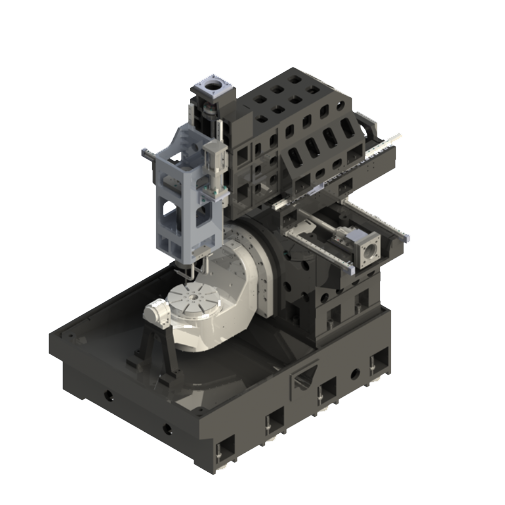

Stability: Machine tool castings

A high-quality, high-rigidity casting is the physical foundation and fundamental guarantee for a 5-axis machining centre to achieve high precision, high stability, high reliability and long service life. Machine tool castings have a crucial and even decisive impact on the stability of machine tools.

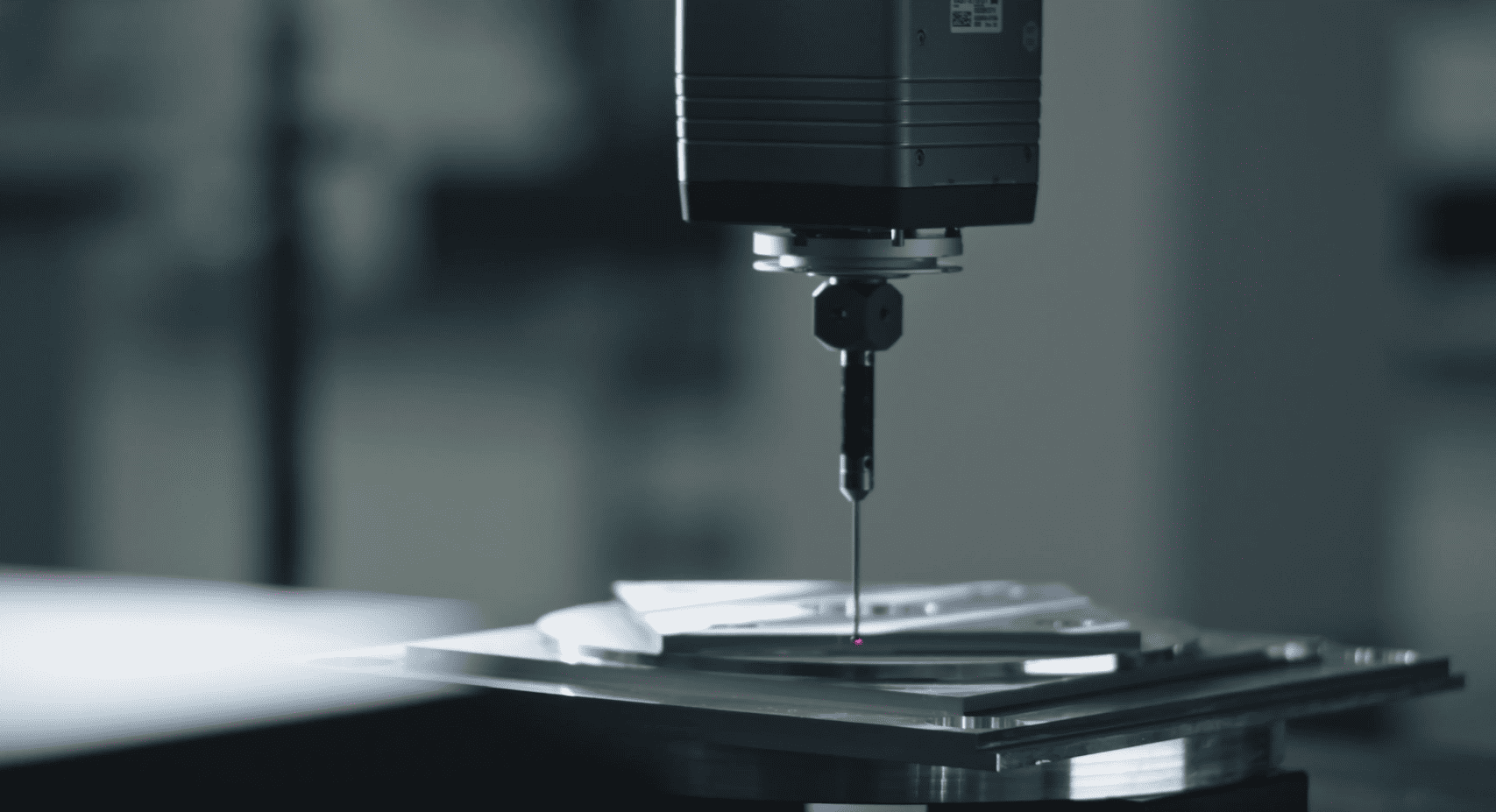

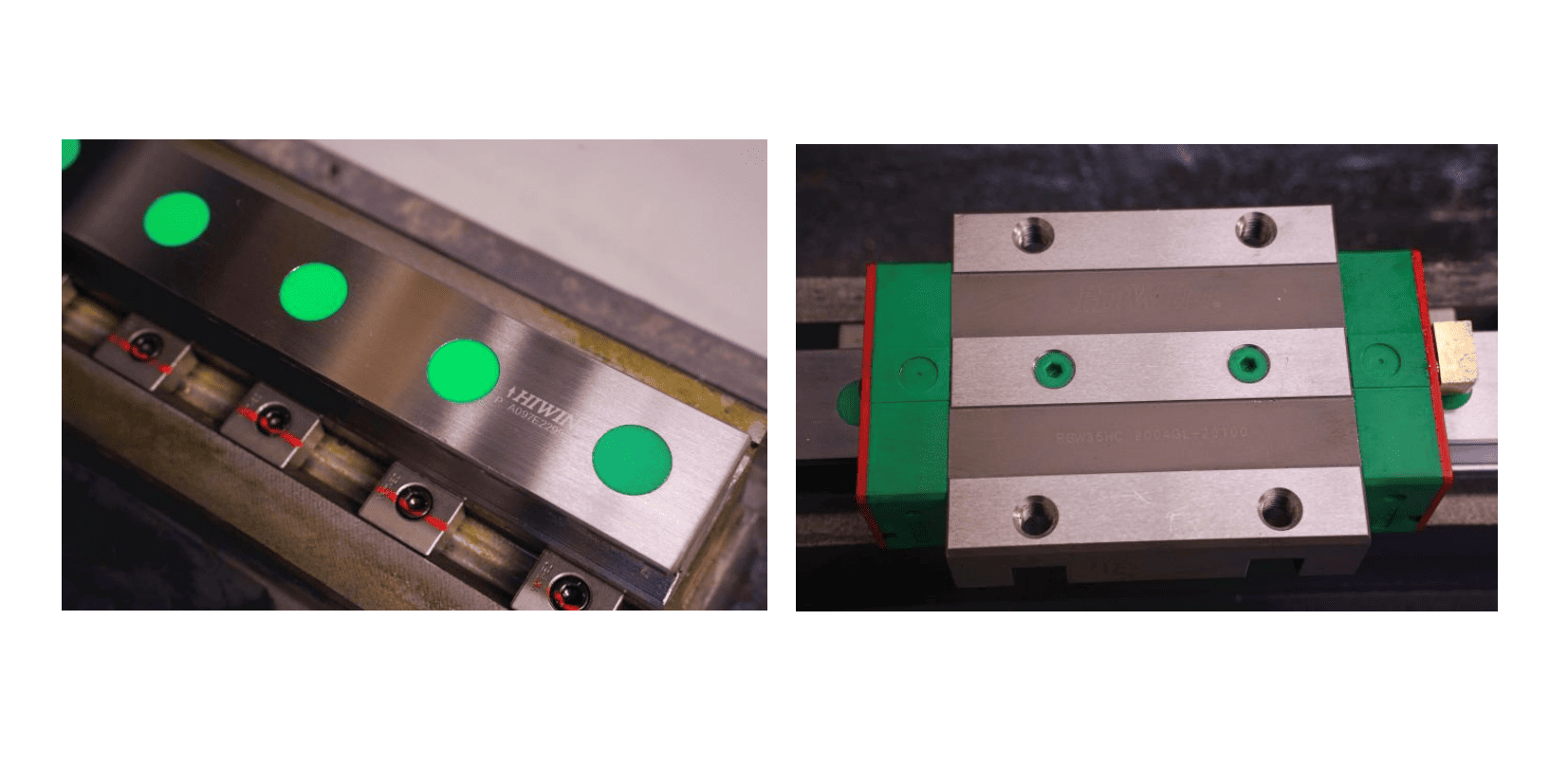

Accuracy: Guide rails and screws

Guide rails and screws are equally important. High-quality, precision-ground components ensure the machine tool’s accuracy and long service life. This is a core component of YOUKA’s quality control process; we conduct mechanical and geometric accuracy tests on every machine tool before it leaves the factory to ensure its performance. YOUKA currently collaborates with HIWIN and THK for rails and screws.

Here is a quick guide to the specified content:

|

Component |

Lower Cost Option | Higher Performance/Cost Option |

Why it Matters |

|

System |

Syntec, HNC, GSK | Fanuc, Siemens |

Reliability, operator familiarity, global support |

|

Spindle |

Lower RPM

Belt-drive |

High RPM, direct-drive |

Matches machine to your materials for best efficiency |

|

Guideways |

Ball-type linear guideways |

Roller-type linear guideways |

Rollers offer higher rigidity for heavy-duty cutting |

|

Screw |

Unknown brand |

HIWIN,THK |

Transmission accuracy |

|

Casting |

Lightweight |

Heavyweight |

Understanding these trade-offs will allow you to configure the 5-axis machining center that’s best for you, ensuring you don’t overpay.

How to verify the quality of overseas manufacturers?

Are you still worried about buying a machine thousands of miles away that you can’t see or touch in person? Sending money overseas without quality verification is a huge risk for any business.

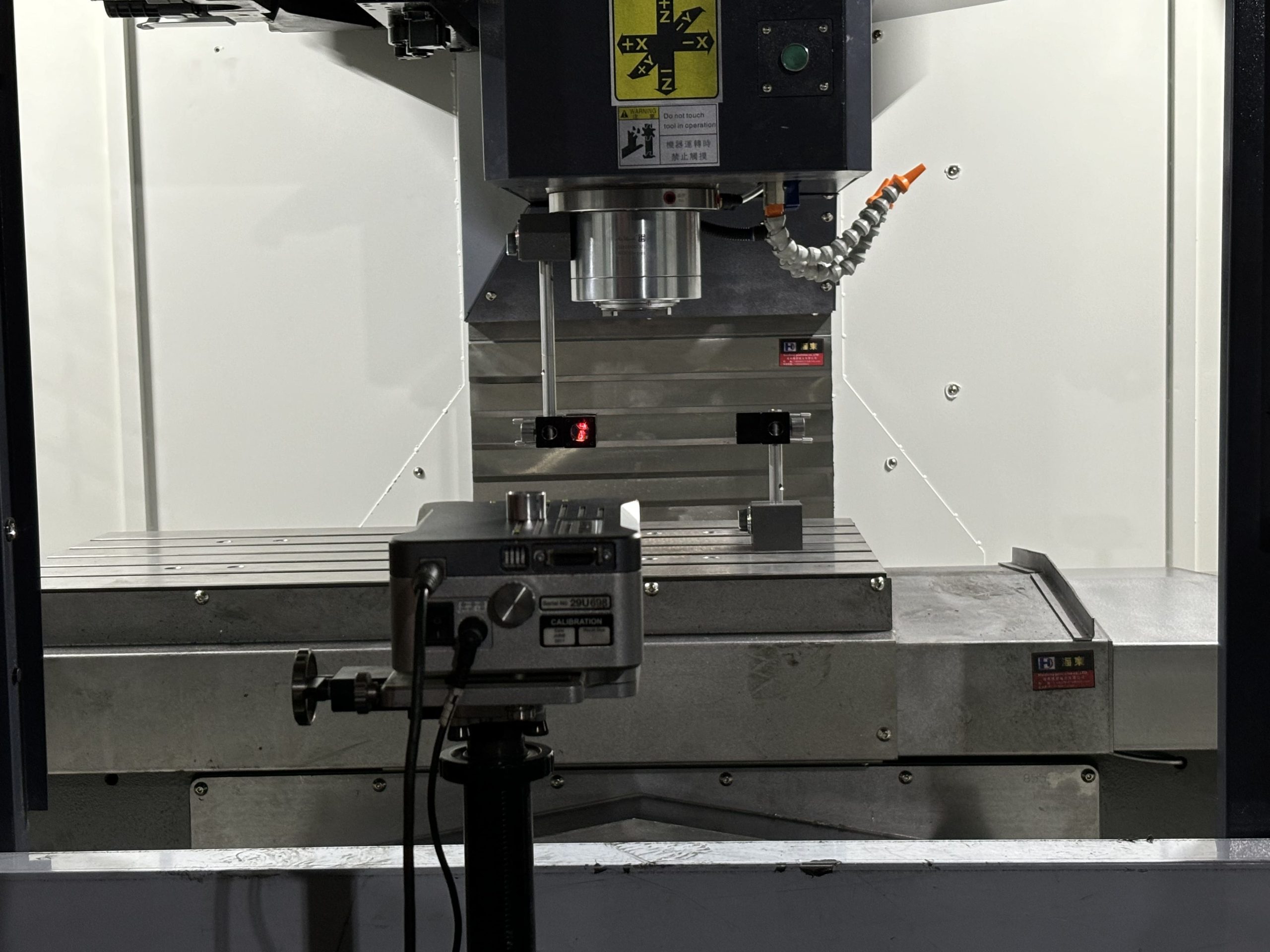

To verify quality, be sure to ask for relevant evidence. Ask for factory photos and videos, ask for a detailed parts list with brand names, and check quality test certificates (such as laser interferometer inspection reports, mechanical accuracy reports, workpiece test videos).

Trust is crucial. As a Chinese manufacturer, I understand buyer hesitation. There are many excellent manufacturers in China, but there are also some trading companies that simply resell the cheapest machines they can find, with no real quality control. You have to do your homework and protect yourself.

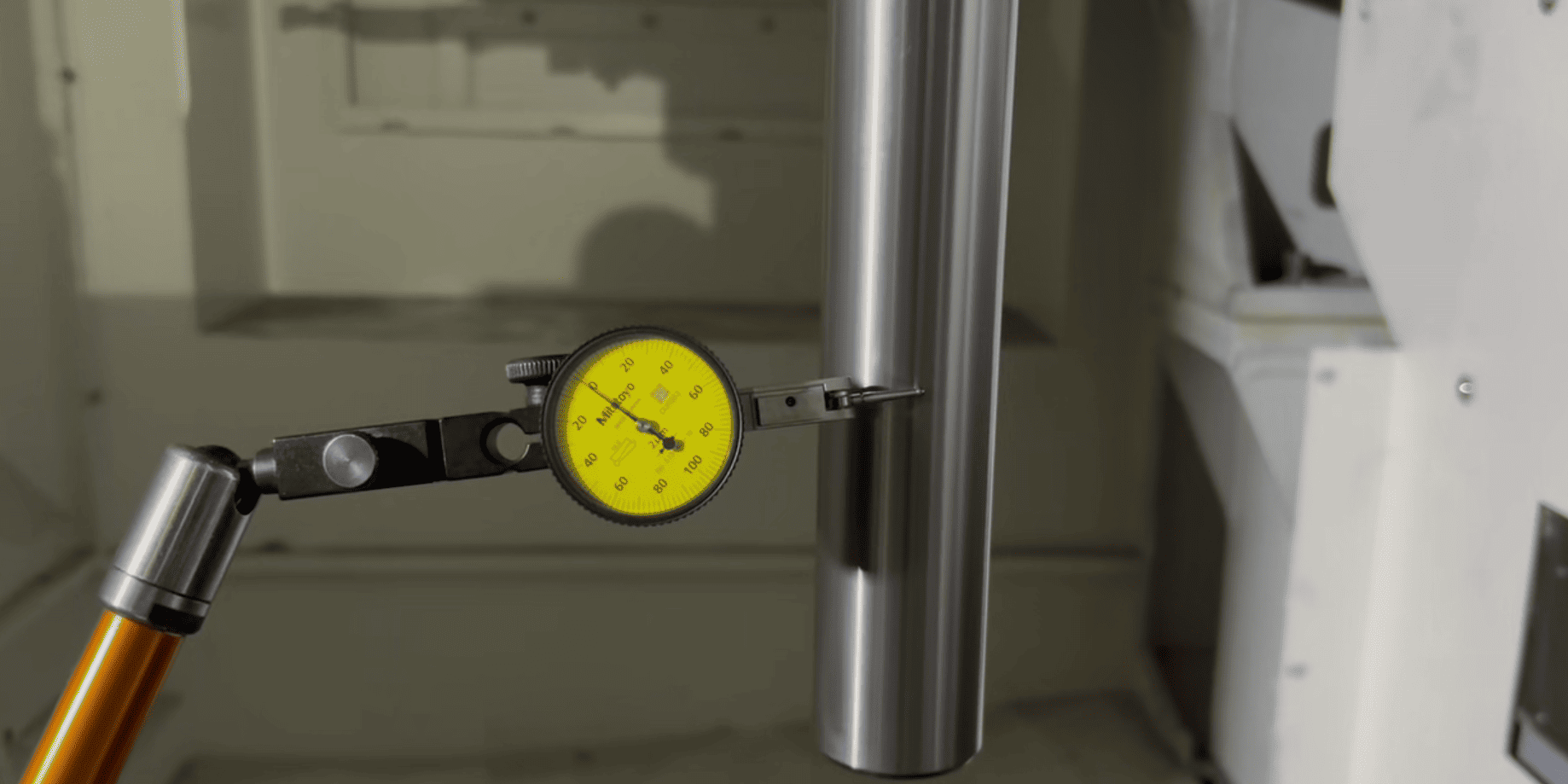

Excellent manufacturers will proudly show you their manufacturing processes. When potential customers request quality certification, YOUKA is happy to provide it. We can conduct real-time video calls at the factory site. I can show them how our testing equipment operates—including laser interferometers for precision checks, ball bar instruments for roundness testing, and leak detection systems for coolant systems. We document every test conducted on every machine we manufacture.

5-axis machining centre quality verification checklist:

· Detailed list of machine parts

· Mechanical accuracy test report

· Geometric accuracy test report

· Water leakage test video

· Electrical leakage test

· Mechanical drawings

· Circuit drawings

· Machine weight

As the manufacturer of China’s first 5-axis machining centre in Shandong Province, YOUKA has paired its machines with HIWIN Torque Motor 650mm Rotary tables. The machines have operated stably for two years in the harsh local environment of our customers, which sufficiently demonstrates the quality of our products. Additionally, our after-sales response time is within 10 minutes. YOUKA has established a good reputation through this transparent and reliable cooperation system. YOUKA is the most cost-effective choice for 5-axis machining centres in China.