You often hear the term “3-axis machining,” but it seems somewhat vague. You need to understand its true meaning to decide if it’s suitable for your workshop.

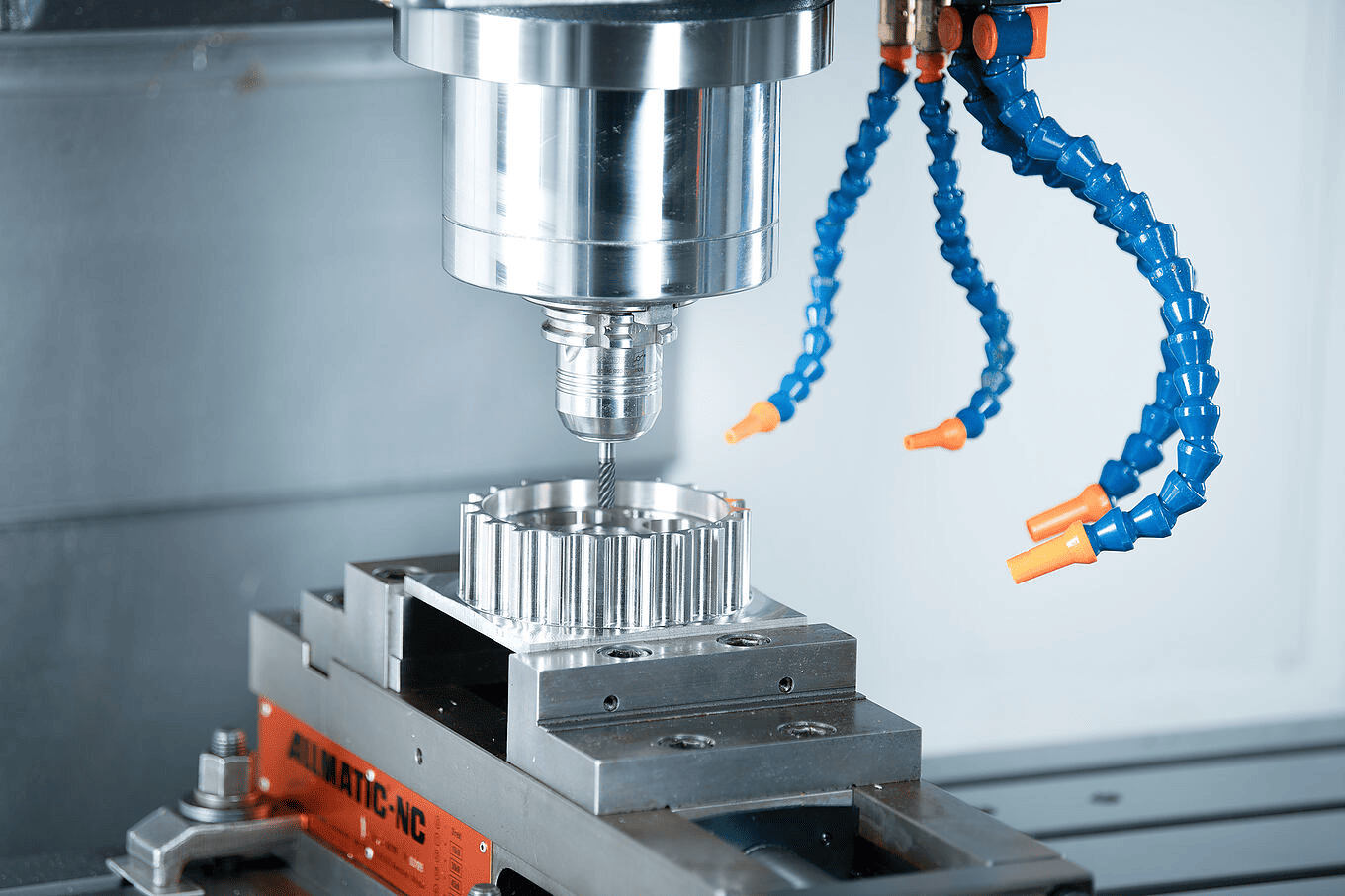

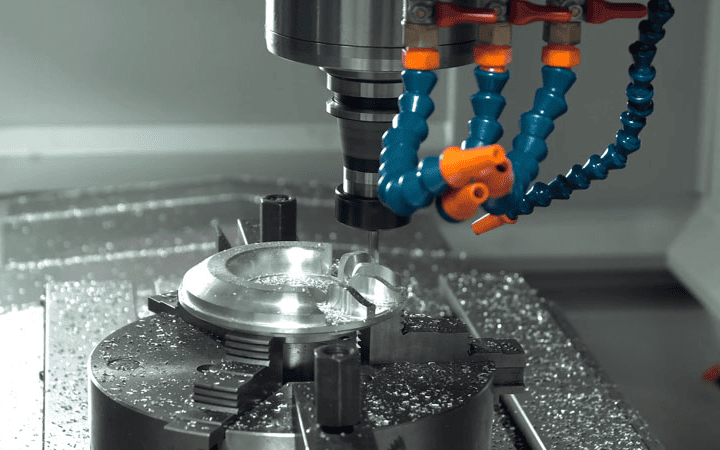

3-axis CNC milling center refers to a machine tool where the cutting tool moves along three linear axes—X (left-right), Y (front-back), and Z (up-down)—to cut a fixed workpiece. It forms the foundation for efficiently producing various prismatic parts.

We have been manufacturing and selling CNC machine tools for over a decade, and it’s safe to say that for most factories, the three-axis vertical machining center is the backbone of their operations. It’s often the first “true” CNC machine a business purchases. While more complex 4-axis and 5-axis machines garner attention, understanding the 3-axis machine is crucial because it handles the majority of the world’s high-paying jobs. Let’s take a closer look at 3-axis machines—how they work and what they can bring to your business.

How Does a 3-Axis CNC Milling Machine Actually Move?

The terms X, Y, and Z axes can seem like abstract geometry. You are not sure how these movements combine to create a finished part, making the process feel overly technical.

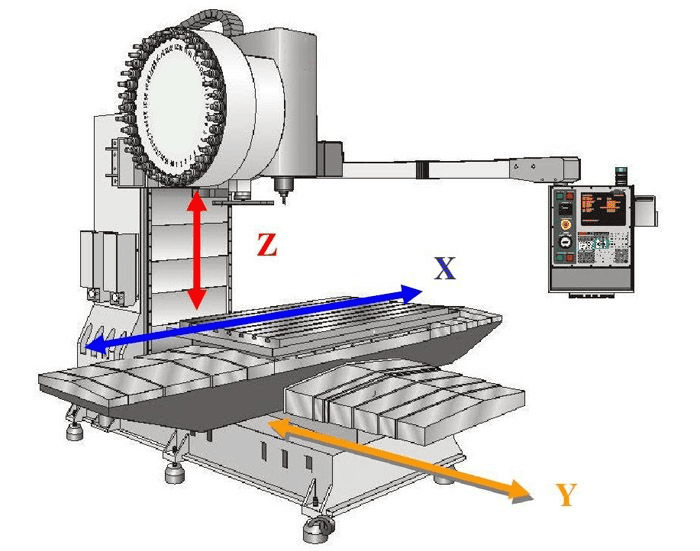

3-axis machine moves the cutting tool left-to-right (X-axis), forward-and-backward (Y-axis), and up-and-down (Z-axis). This combination of three simple, linear movements allows the machine to carve material from a block held stationary in a vise or fixture.

To really understand this, we need to look at the machine from the operator’s perspective. In a standard Vertical Machining Center (VMC), which is the most common type of 3-axis machine, the “axes” refer to the specific directions the machine components move.

The Three Linear Axes

The machine’s computer controller directs motors to move these components along precise paths.

· X-Axis: This is the table’s movement from left to right. Imagine the workpiece sliding left and right under the stationary spindle. This is the longest axis of travel on most machines.

· Y-Axis: This is the table’s movement from front to back. Imagine the workpiece moving toward you and away from you.

· Z-Axis: This is the spindle’s movement up and down. This brings the cutting tool into the material to make cuts or retracts it to move to a new position.

When the computer controller (the CNC) combines these movements, it can guide the cutter to any point in that 3D box. However, it is important to remember that strict 3-axis machines cannot tilt the tool. The tool always stays straight up and down.

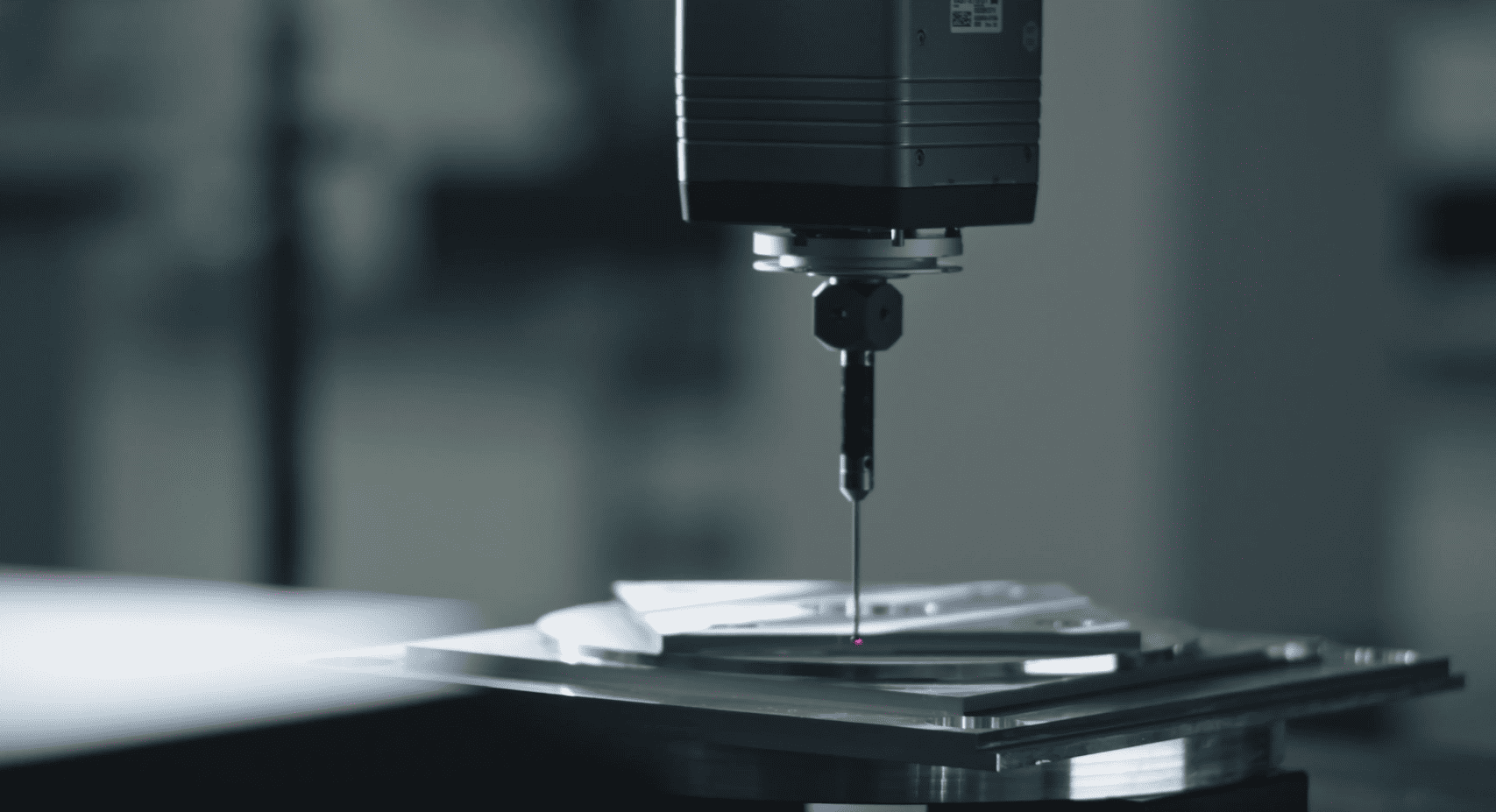

In my factory, we pay massive attention to the precision of these three movements. We use laser interferometers to check that when the screen says the machine moved 100mm, it actually moved exactly 100mm. Even a tiny error in these basic linear movements can ruin a part. So, while the concept of “3-axis” is simple, building a machine that does it consistently for years requires strict geometric testing and quality control. This reliability is what I offer my customers.

Now that we understand the movement, you might be wondering what specific shapes this machine can actually create.

What Kind of Parts Can You Make With a 3-Axis Machine?

You have a complex part design but wonder if a basic 3-axis machine can handle it. You fear investing in a machine that is too limited for the jobs you want to win.

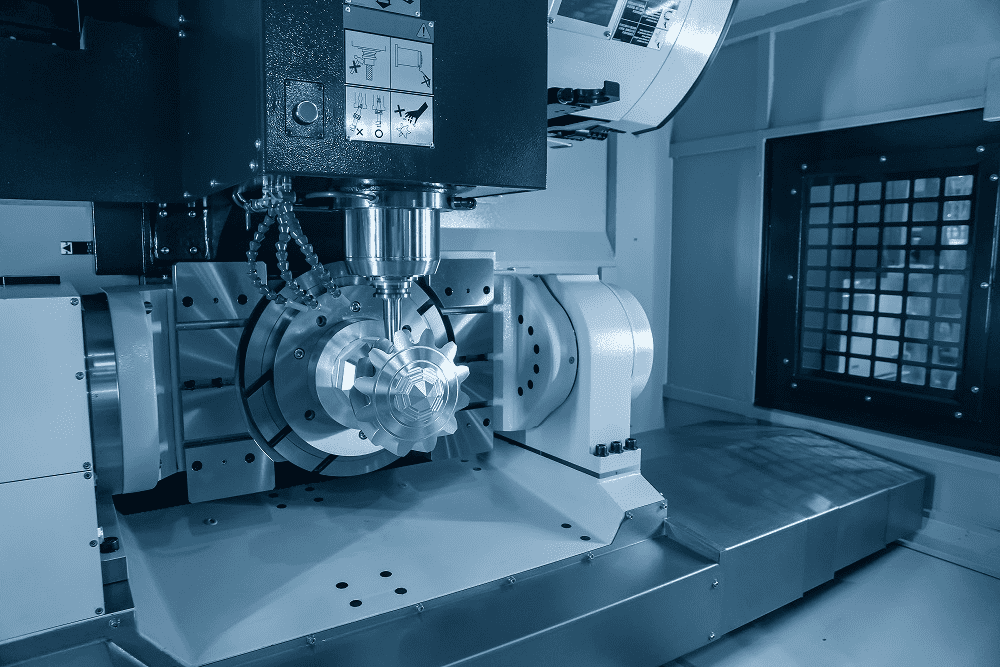

A 3-axis machine excels at creating “prismatic” parts, which are generally boxy or have features accessible from the top side. They are perfect for producing plates, brackets, simple molds, and any component that can be machined in one or more flat orientations.

The phrase I use with my clients is: “If you can see it from the top, a 3-axis can cut it.” This is a simplification, but it is a great starting point for understanding the machine’s capabilities.

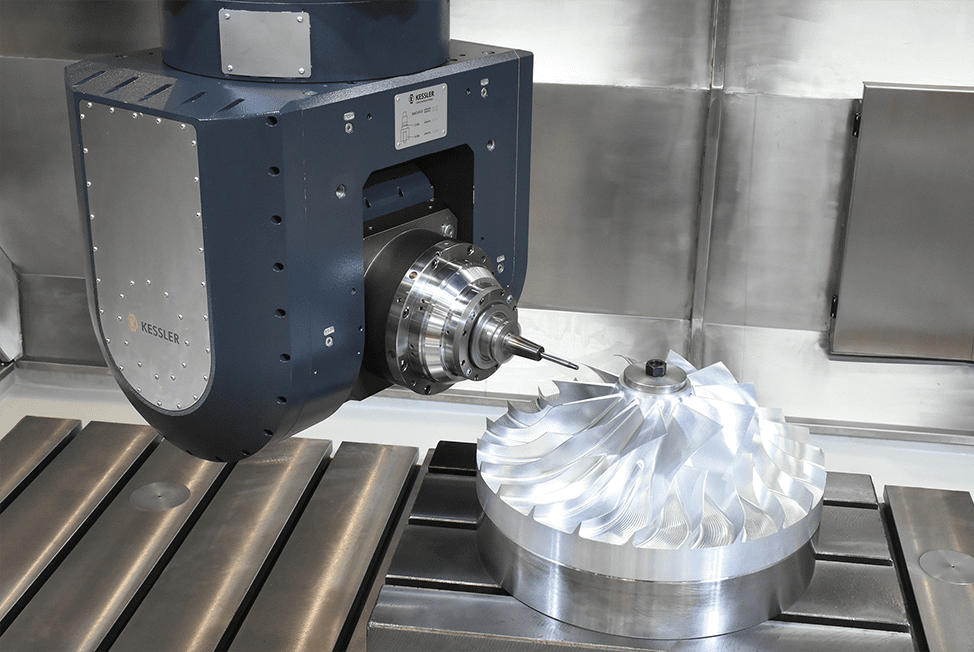

A 3-axis machine is perfect for drilling holes, tapping threads, cutting flat surfaces (facing), and milling pockets or slots. It can also do “3D contouring,” which means moving X, Y, and Z at the same time to create smooth, curved surfaces, like the hood of a car or a computer mouse mold. However, because the tool cannot tilt, it cannot reach underneath the part (undercuts).

Here is a breakdown of typical projects I see my customers running:

| Part Type | Description | Suitability for 3-Axis |

| Engine Plates | Flat metal plates with many holes | Perfect |

| Enclosures | Aluminum boxes with pockets | Perfect |

| Simple Molds | Cavities for plastic injection | Excellent |

| Turbine Blades | Curved, twisted shapes | Difficult (Need 5-Axis) |

If you need to machine the side of a part on a 3-axis machine, you have to stop the machine, take the part out, flip it over, and clamp it down again. This is called a “setup.” While 3-axis machines are limited to one side at a time, smart machinists use them to make incredible things just by rotating the part manually.

So, if 3-axis machines have limitations, why do they remain the most popular choice in the industry?

Why Is the 3-Axis VMC Still the King of the Workshop?

You see all the marketing hype about expensive 5-axis machines. You worry that buying a standard 3-axis machine means investing in outdated technology that will put you behind the competition.

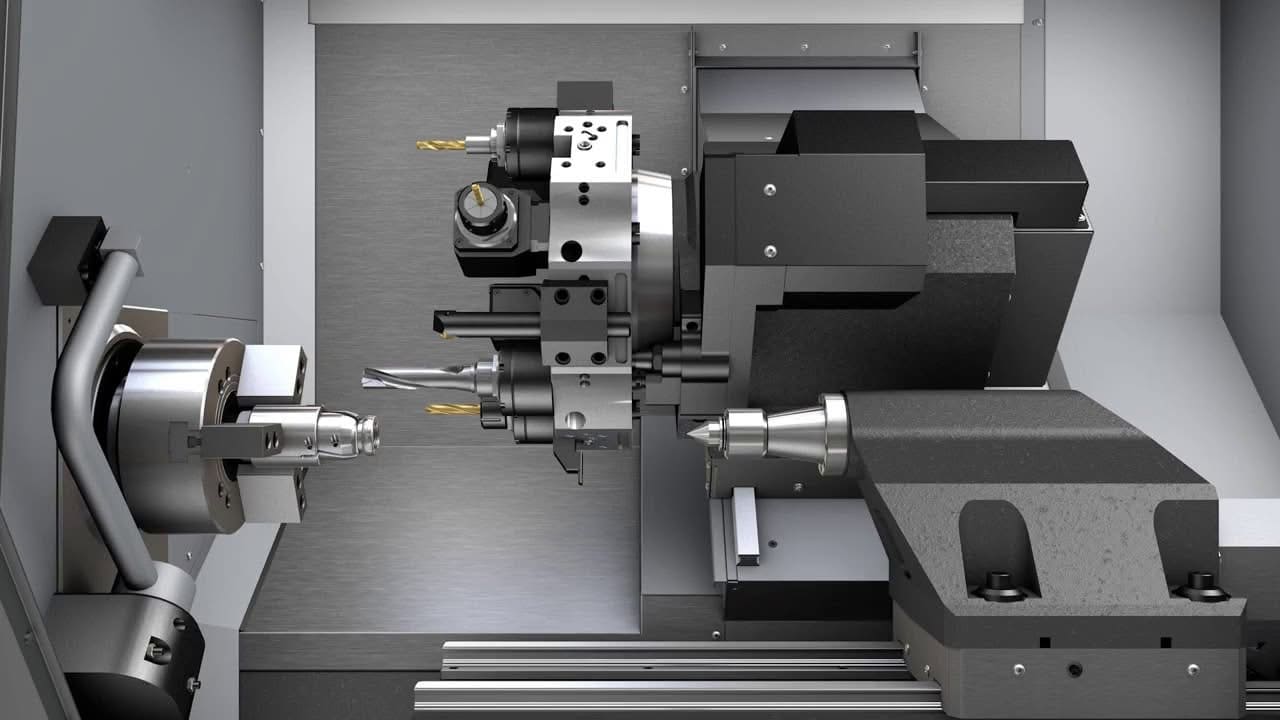

The 3-axis VMC remains the industry king because it offers the best balance of cost, versatility, and ease of use. It handles 80% to 90% of all manufacturing jobs at a fraction of the cost of complex multi-axis machines.

Do not let the hype fool you. For most diverse job shops and traders, a robust 3-axis machine is the smartest financial move. I have helped many businesses start, and I almost always recommend starting here.

In my experience, there are three main reasons why 3-axis machines dominate the market:

1. Lower Initial Investment: A good 3-axis machine from YOUKA costs significantly less than a 5-axis machine. This means your Return on Investment (ROI) is much faster. You do not need to charge premium prices to make a profit.

2. Ease of Operation: Finding an operator who can run a 3-axis machine is easy. Finding someone who can program and run a 5-axis machine is hard and expensive. The programming is simpler, the setup is straightforward, and the margin for error is more forgiving.

3. Lower Maintenance Costs: With fewer moving parts, there is less that can go wrong. A 3-axis machine is simpler to service and cheaper to fix.

At YOUKA, we focus on making these “workhorse” machines as efficient as possible. We use heavy castings and high-quality linear guides to ensure that even though the machine is standard, the performance is premium. We help you reduce production costs not by selling you the most expensive toy, but by selling you the most reliable tool. Whether you are cutting steel, aluminum, or plastic, a rigid 3-axis machine allows you to bid on the vast majority of contracts available in the market today.

3-axis CNC milling center moves in X, Y, and Z directions to cut parts. It is the most cost-effective, versatile, and essential machine for any manufacturing business.