Still struggling with complex parts and cumbersome clamping operations? Each setup wastes time and is prone to errors, which can seriously erode your profits. A 5-axis machine tool may well be the solution to this problem.

A 5-axis machining center is a CNC machine tool capable of simultaneously moving the tool or workpiece along five distinct axes, achieving five-axis five-axis simultaneous control. This design enables the machining of highly complex shapes with a single setup, delivering significant improvements in both efficiency and precision compared to simpler CNC machine tools.

This seemingly straightforward definition is ubiquitous. Yet, drawing upon my decade of experience manufacturing and marketing these machines at YOUKA, I can assure you that true value lies in the details. To genuinely ascertain whether a five-axis machine represents the right investment for your workshop, we must delve into its capabilities, its distinguishing features, and its implications for your day-to-day operations.

What distinguishes five-axis machine tools from standard three-axis machine tools?

Are the capabilities of your three-axis machine tool limited? For any workshop owner, having to abandon complex, high-margin machining tasks due to technical constraints is a frustrating experience.

Different trajectories

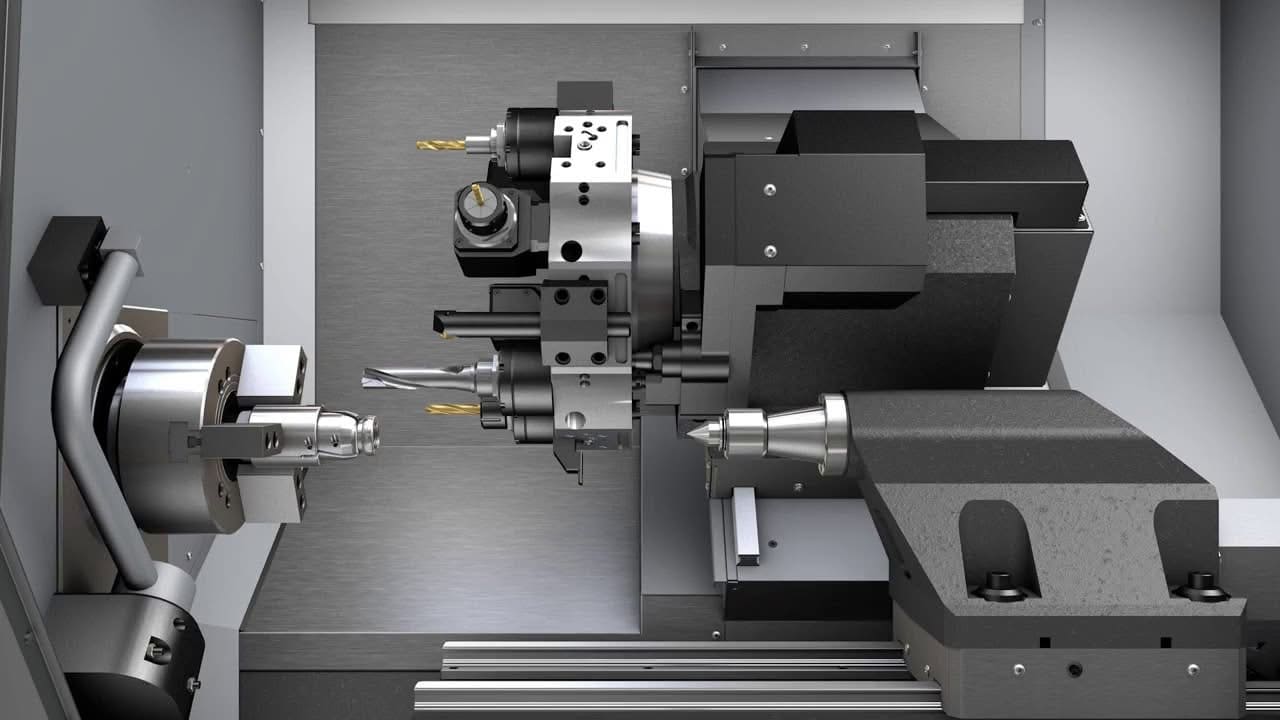

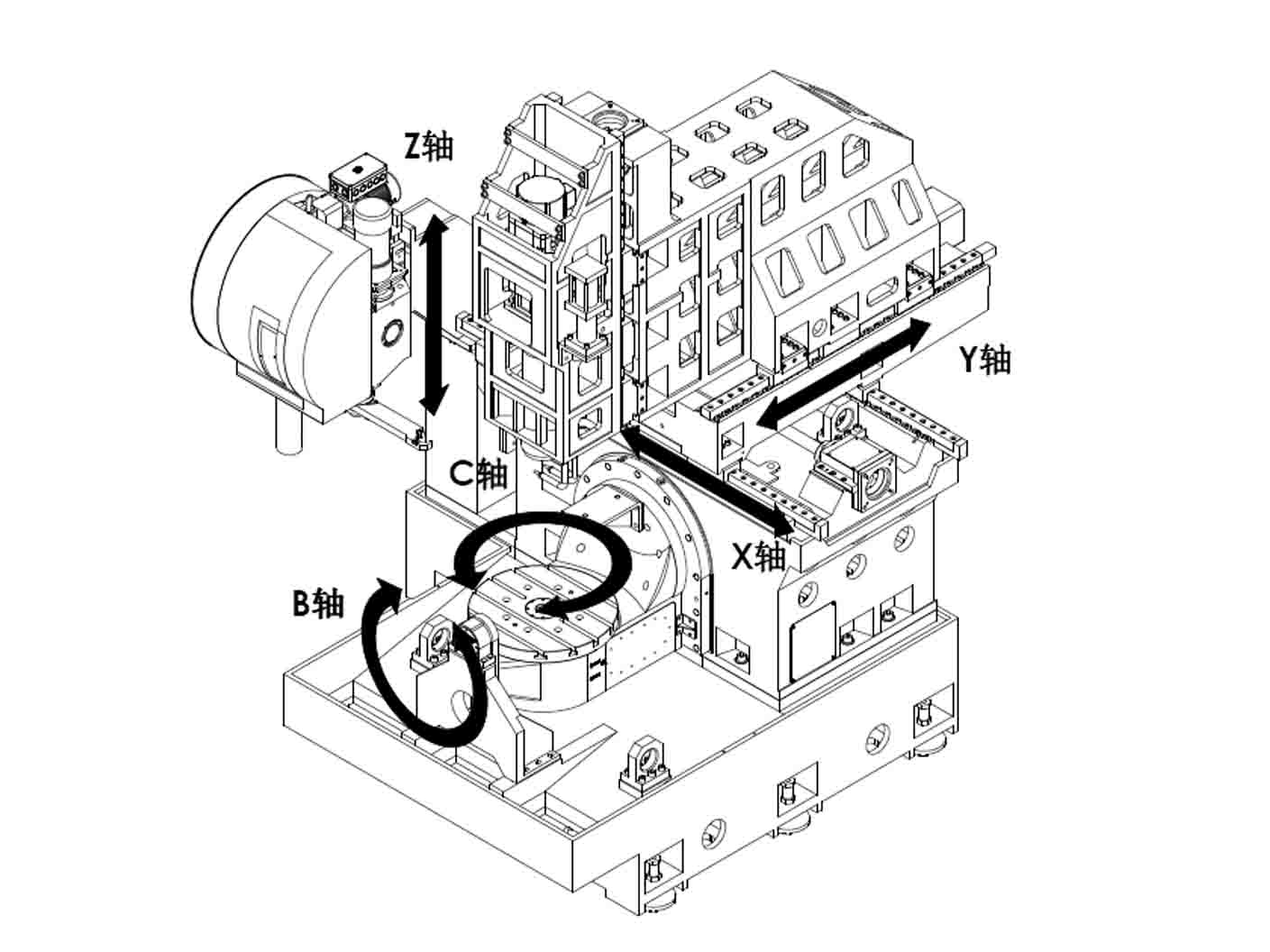

The primary distinction between five-axis and three-axis machine tools lies in their motion capabilities. Three-axis machines operate along three linear axes (X, Y, and Z). Five-axis machines incorporate two additional rotary axes (A and B or C), enabling the tool or workpiece itself to tilt and rotate, thereby machining five sides of a part in a single setup.

· Linear axes: The most common are the three linear axes: X, Y, and Z.

· X-axis: Typically represents the table moving left and right.

· Y-axis: Typically represents the spindle head moving forwards and backwards.

· Z-axis: Typically represents the spindle moving up and down.

· Rotary axes: In addition to the three linear axes, five-axis machining centres feature two rotary axes, typically denoted by two of the following: A, B, or C.

· A-axis: Rotation about the X-axis.

· B-axis: Rotation about the Y-axis.

· C-axis: Rotation about the Z-axis.

Therefore, a 5-axis machining center comprises three linear axes (X, Y, Z) plus two rotary axes (typically A and B, or B and C, among other combinations). This configuration permits simultaneous movement of the tool or workpiece across five degrees of freedom.

Let us delve deeper. Having spent thousands of hours on both types of machine tools, their distinction extends far beyond merely having two additional axes. It represents an entirely different manufacturing philosophy. Three-axis machines are suited for machining simpler components, such as plates or blocks featuring only top-surface features, where the tool moves left and right (X-axis), forward and backward (Y-axis), and up and down (Z-axis). It is straightforward and efficient.

However, should you need to machine features on the part’s side, you must halt the machine, release the workpiece, manually rotate it, re-clamp it, and establish a new datum. Each time these steps are performed, there is a slight risk of error.

Five-axis machine tools can eliminate most such manual operations. The two additional rotary axes enable the machine itself to tilt the part or the cutting tool. Consequently, it can machine complex curves, undercuts, and inclined holes without requiring the part to be released from the vice.

Operational differences

The following table illustrates the core differences from a practical perspective:

|

Feature |

3-Axis Machining Center |

5-Axis Machining Center |

|

Axes of Motion |

X, Y, Z (Linear) |

X, Y, Z (Linear) + A, B/C (Rotational) |

|

Setups per Part |

Multiple setups for complex parts |

Often a single setup (“done-in-one”) |

|

Part Geometry |

Best for 2D and 2.5D shapes |

Ideal for complex 3D contours and multi-sided parts |

|

Tool Length |

Often needs longer tools for deep pockets |

Can use shorter, more rigid tools for a better finish |

|

Lead Time |

Longer due to repeated setup time |

Shorter, as setup time is drastically cut down |

|

Accuracy |

Risk of error increases with each new setup |

Higher accuracy, as the part is not moved |

Ultimately, five-axis machining represents not merely a minor upgrade, but a significant enhancement to a workshop’s machining capabilities. It can effortlessly accomplish machining tasks that are either impossible or fundamentally unprofitable on three-axis machines.

What are the main types of five-axis machines?

Still confused by industry terms like ‘ear-axis’ or ‘rotary head’? Selecting a machine tool configuration unsuited to your machining requirements can lead to costly errors.

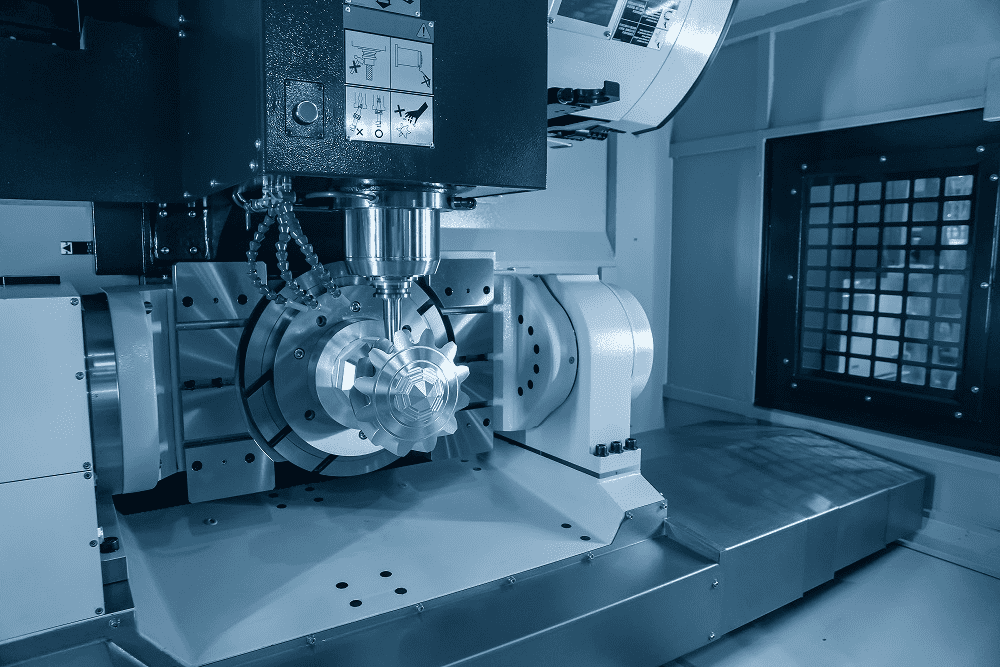

The primary types of five-axis machining are defined by how the rotary axes function. In ear-axis machines, the worktable can rotate and tilt the workpiece. In rotary-head machines, the machine’s spindle head can rotate and tilt the tool, while keeping the workpiece more stable.

Drawing from my experience manufacturing these machines at YOUKA, the configuration you select profoundly impacts the types of work you can efficiently accomplish. Neither type is universally superior; they are simply engineered for different applications. Let us examine the specifics.

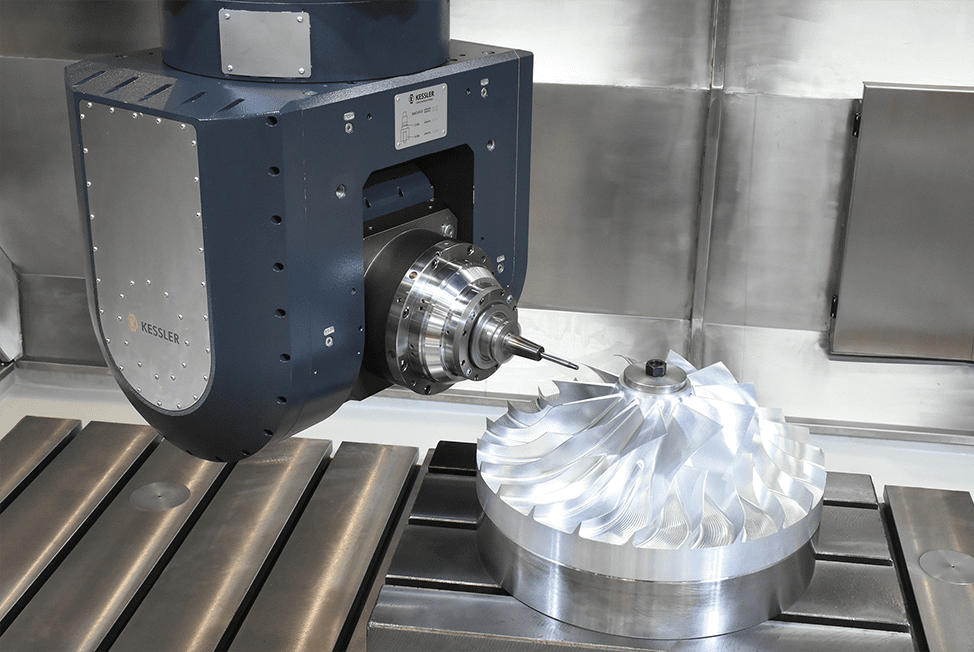

Trunnion-type machine tools

On trunnion-type machine tools, the worktable itself supports the workpiece and rotates it on the A and C axes, while the spindle moves along the standard X, Y, and Z axes. This can be conceptualised as the machine tool moving the part around the tool. It is a highly prevalent and effective design. Due to the part moving and rotating, practical limitations exist regarding the workpiece’s dimensions and weight. I have observed clients overloading the trunnion, which places significant stress on rotating components and may compromise long-term accuracy. Nevertheless, this configuration offers excellent access for undercuts and a spacious, unobstructed working area when machining smaller, intricate parts.

Rotary Head Machines

On rotary head machines, the worktable is typically stationary or moves only along the X and Y axes. The true ingenuity lies in the spindle head, which rotates around the B-axis and C-axis. This means the tool moves around the part. The immense advantage of this design is that very large and heavy parts can be placed on the worktable, as the table itself does not need to support these weights during rotation. This makes them exceptionally well-suited for machining large moulds, automotive dies, and substantial aerospace components. However, a drawback is that the large rotary head mechanism can sometimes limit machining capacity compared to similarly sized spindle-type machines.

Below is a quick guide I shared with the client:

|

Aspect |

Trunnion Style |

Swivel Head Style |

|

Moving Component |

Workpiece rotates and tilts |

Tool head rotates and tilts |

|

Best For |

Smaller, more complex parts |

Very large and heavy parts |

|

Workpiece Weight |

Limited by table’s rotary capacity |

Much higher weight capacity |

|

Work Envelope |

Generally larger and less restricted |

Can be restricted by spindle housing |

|

Typical Industries |

Medical, electronics, small complex parts |

Aerospace, Automotive, Mold & Die |

When clients ask me which model to choose, my first question is always: ‘What is the average size and weight of your components?’ The answer usually points us in the right direction.

What are the practical advantages of using five-axis machine tools?

Do you believe five-axis machine tools are only suitable for complex aerospace components? This common misconception could be costing you efficiency and profit in your daily operations.

The foremost advantages of five-axis machining lie in reduced set-up times, enhanced precision, and improved surface finish. By machining parts in a single setup, you eliminate errors caused by re-clamping and can utilise shorter, sturdier cutting tools for smoother, faster cutting.

Over the years, I’ve been delighted to witness clients transform their workshops after installing their first five-axis machine. The benefits of five-axis machining extend far beyond producing ‘more beautiful’ parts. The real magic lies in how it enhances the entire manufacturing process, even for seemingly straightforward tasks.

Lead Times and Labour

First, let’s address lead times and labour. Imagine a part requiring machining on six distinct sides using a three-axis vertical machining centre (VMC). This necessitates six separate setups. Each setup requires the operator to spend time cleaning the vice, clamping the part, finding a new zero point, and loading the correct programme. With a five-axis machine, you only need to complete one setup. This ‘one-off’ approach can reduce work that would take days to complete to just one day. This means you can quote faster delivery times to customers and accomplish more work with the same number of staff.

The Overlooked Advantage of Short Tools

One frequently overlooked advantage in discussions is tool usage. On three-axis machines, accessing deep cavities or bypassing certain features often necessitates mounting long cutting tools on extended tool holders. These lengthy tools suffer from reduced rigidity and increased vibration, leading to chatter, poorer surface finish, and forcing operation at lower cutting speeds. With a five-axis machine, you can tilt either the tool or the part. This allows you to access the exact same area from different angles using shorter, more stable tools. Shorter tools mean you can run the machine faster, achieve superior surface finishes, and extend tool life itself. This reduces your tooling costs while enhancing the quality of every part you produce.

A five-axis machining centre is a high-end CNC machine tool that integrates two rotary axes with three linear axes. This enables the tool to perform high-speed, high-precision, complex machining operations on workpieces from any spatial direction. Complex parts can be machined in a single setup. This saves time and represents the ultimate solution for modern manufacturing to process intricate, precise, high-quality components, embodying the pinnacle of CNC machining technology.